Comparison Between Cold/Hot Smart Water Flooding in Sandstone Reservoirs - Juniper Publishers

Juniper Publishers - Open Access Journal of Engineering Technology

Abstract

The incremental oil recovery has been investigated

and approved by many laboratory and field projects using water flooding

in tertiary stage. The salinity of the injected water is an important

factor observed by many researchers. The more salinity decreases the

more oil recovery obtained. The investigations on the hot low salinity

water flooding have been conducted by many researchers and they found

out that it is useful for increasing oil recovery especially heavy oil

due to reducing oil viscosity and make it easy to produce to the

surface. The thermal expansion of water plays an important role in the

incremental oil recovery mechanism, reducing the density of the injected

water relative to the aquifer water. This reduces mixing, minimizing

thermal loses to the aquifer.

Hot water flooding may also increase the economic

life of individual wells by as much as a factor of two. Smart water was

also used to alter the reservoir wettability and increase oil recovery

by manipulating the divalent cations in the injected water. In this

study, we used hot and cold smart water and injected both into the

sandstone saturated with crude oil in order to investigate the important

role of smart water itself and hot smart water. The systematic results

showed that changing some cations in the injected brines was better than

to spend more money to heat the smart water. The divalent cations Ca2+

and Mg2+ was the most effective component in the smart water. In this

study, we also studied the pH effect of the cold/hot smart water

effluent smart water EOR.

Keywords: Smart water

flooding; Sandstone reservoirs; Incremental oil recovery; Field

projects; Salinityinvestigations; Aquifer; Rod sucker pumpsIntroduction

Eastern Kansas oil fields contains heavy oil that is

produced via rod sucker pumps. The daily production fromBartlesville

Sandstone reservoir is around 500bbl/day with high water cut. Such

reservoirs have a low temperature and the oil viscosity of several

hundreds of centipoises. The mobility ratio is quite different between

the water and the heavy oil and if a conventional water flooding would

be conducted, the oil recovery could be low. A higher temperature of the

water flooding prompt to reduce the oil viscosity. The hot injected

water also could reduce the unequal viscosity of the water and the oil

in the heated zone, and in turn, the sweep efficiency could be improved.

In this work, we injected smart water because of its

results in increasing oil recovery according to many labs works and

pilot based on the mechanisms that propose and qualify the effectiveness

of smart water flooding such as: multicomponent ion exchange[1],

double-layer expansion [2], reduction in interfacial tension and

increased pH [3],fines mobilization [4],

mineral dissolution [5], organic material desorption from the clay

surface [6], Cation exchange on quartz surface [7], desorption of

organic materials from quartz surface [8].

In the case of using thermal EOR techniques, the heat

provided to the reservoir could absolutely reduce the oil viscosity and

increase oil recovery. The economic overview, on the other hand, the

least expensive thermally technique is hot water flooding based on oil

recovery [9-11]. In this work, a combined chemical and thermal

technology was applied on Bartlesville Sandstone cores to find a

feasible, cost-effective EOR solution to increase oil recovery from

heavy oil reservoirs without using high energy methods such as thermal

techniques.

Experimental Section

Porous Media

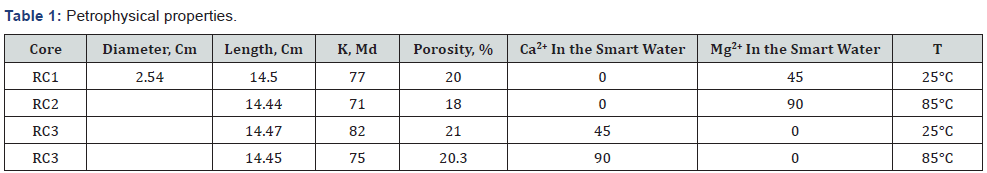

Core samples were taken from the Bartlesville

Sandstone reservoir located in east Kansas. The cores description is

listed in Table 1.

Brines and Crude Oil

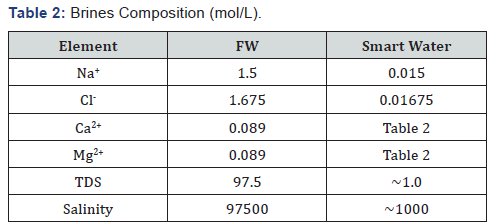

Reagent-grade salts were prepared with deionized water to

make FW and smart water. The compositions of brines are listed

in Table 2. A reservoir crude oil was delivered by Colt Energy

from Bartlesville Sandstone reservoir. The oil viscosity is ~600

cp and density 0.83 at 20°C.

Core Preparation and Flooding

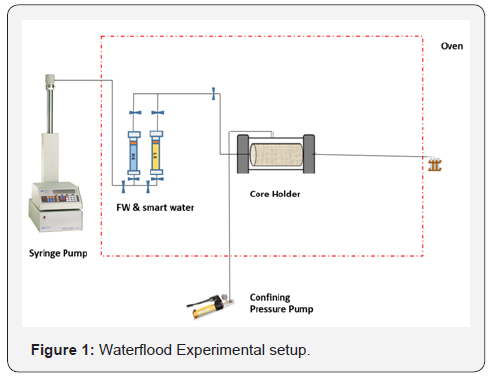

The experimental setup is shown in Figure 1. The cores

first cleaned with toluene. The cores were then evacuated and

saturated under vacuum in the FW. The same FW was used to

measure the permeability. The cores were pre-aged in heavy

crude oil for three weeks at 90°C. The water flooding was

conducted at reservoir temperature 90°C. FW was injected into

the cores until residual oil saturation was reached. After that,

smart water was injected until no more oil was produced and

injection pressure stabilized. The cores were saturated with the

same FW and smart water was injected as follows:

i. RC1: The smart water contains 45mmole of Ca2+, and

the experiment temperature was 25°C.

ii. RC2: The smart water contains 90mmole of Ca2+, and

the experiment temperature was 85°C.

iii. RC3: The smart water contains 45mmole of Mg2+, and

the experiment temperature was 25°C.

iv. RC4: The smart water contains 90mmole of Mg2+, and

the experiment temperature was 85°C.

Results and Discussion

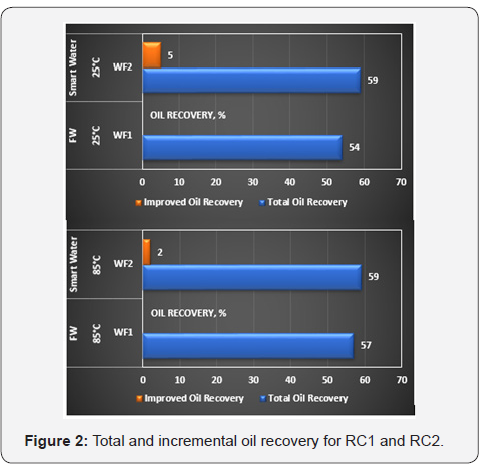

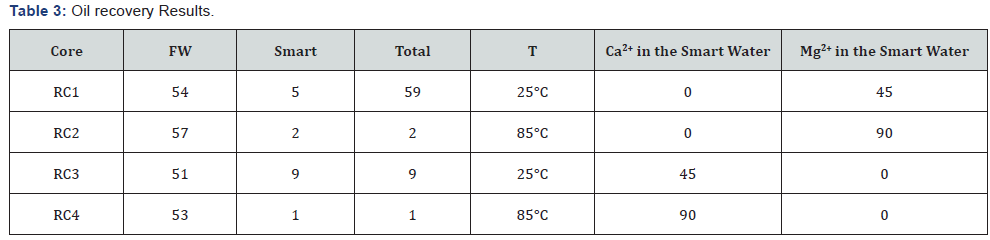

Reservoir core (RC1) and RC2 were flooded with smart water

containing 45 and 90mmole Mg2+ at 25°C and 85°C, respectively

as described in Table 2, while both RC3 and RC4 were flooded

with smart water containing 45 and 90mmole Ca2+ at 25°C and

85°C, respectively.

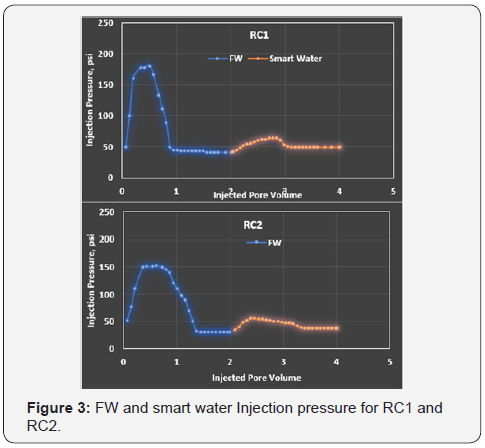

RC1

The temperature of this experiment was set on 25°C. The core

successively flooded with FW and smart water. The volume of the

produced oil was collected and logged at the room temperature.

The pressure readings were also recorded. The ultimate oil

recovery was 54% of original oil in place (OOIP) after the core

flooded with FW (Figure 2). The injection pressure started with

50 psi and rose up to 180psi and dropped until stabilizingat

41psi after injecting 2PV of FW (Figure 3). The incremental

oil recovery after switching the injected brine to smart water

was 5% of OOIP. The injection pressure rose up to 64psi and

stabilized at 49psi.

RC2

This core was flooded the same way as RC1 except the smart

water containing 90mmole of Mg2+. The temperature was

85°C for both FW and smart water flooding. The oil recovery

during secondary water flooding with FW was 57% (Figure 2),

the flooding was stopped after injecting 2PV of FW. The water

injection stopped until no more oil was produced and until

the pressure stabilized. During the FW flooding, the pressure

started 52psi. The pressure increased quickly until reaching the

maximum reading at 151psi. After the crude oil began to flow out

the core, the pressure decreased slowly until stabilizing at 31psi.

Upon switching to smart water, the incremental oil recovery was

2% of OOIP. The injection pressure increased dramatically until

reaching the highest point which was 51psi and stabilized at that

point.

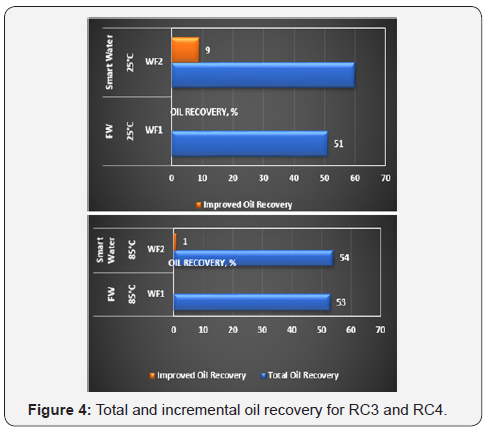

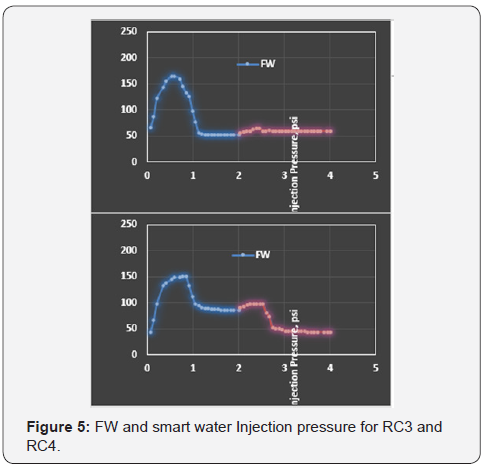

RC3

This core and the following one (RC4) were flooded with

smart water containing 45 and 90mmole of Ca2+ at 25 and 85°C,

respectively. The experiment temperature is 25°C for RC3. The

oil recovery with FW was 51% of OOIP (Figure 4). The injection

pressure started with 66 psi and rose up to 160psi and then

stabilized at 52psi (Figure 5). Upon switching to smart water, the

improved oil recovery was 9% of OOIP. The injection pressure

stabilized at 59psi.

RC4

The experiment temperature was set at 85°C. The same

procedure was followed as in previous cores. After injecting

2PV of FW the oil recovery was 53% of OOIP. The recovery was

improved to 54% after the injected brine switched to smart

water, resulting in a 1% incremental recovery of OOIP. The

injection pressure stabilized at 43psi.

All Cores were similar in FW but different in the experiment

temperatures and the injected smart water. Both RC1 and RC2

were flooded using 45 and 90mmole of Mg2+ in the smart water

but at 25°C and 85°C.

Increasing concentration of Mg2+ in smart water has the

effect on reducing oil recovery during smart water flooding.

Comparing RC1 and RC2, the oil recovery from RC1 by FW was

54% of OOIP, while it was 57% of OOIP from RC2. The ultimate

oil recovery in RC2 was higher than in RC1 because the higher

temperature.

The incremental oil recovery from RC1 using smart water

was 5% of OOIP, while it was 2% of OOIP from RC2; i.e. the

improved oil recovery decreased by a factor of 2.5 when doubling

the concentration of the Mg2+ in the injected smart water even

though the temperature was higher for RC2. Similarly, comparing

RC3 with RC4, the oil recovery was 51% of OOIP for RC3 with FW

flooding, while it was 53% for RC4 also due to extra heat.

The incremental oil recovery using smart water flooding

was 9% of OOIP for RC3, while it was only 1% of OOIP for

RC4; i.e. the improved oil recovery increased by a factor of 9 if

we reduced the concentration of the Ca2+ in the injected smart

water although the temperature was ambient temperature.

Increasing the divalent cations in the injected smart water led

to decrease the adsorption of the organic material, and in turn,

the rock became too water-wet for observing smart water effect.

During FW flooding, comparing all the cores in this work, the

higher the temperature, the higher the oil recovery. Using hot

water improves the mobility ratio due to reducing the oil phase

viscosity compared with cold water. Thermal expansion of water

plays an important role in injecting hot water, the lower density

of hot water reduces thermal loses to the aquifer and speeds up

the propagation of the temperature front through the reservoir.

The effect of increasing the temperature to 85°C with a

double Mg2+ concentration in smart water (RC2) is the same as

applying 25°C with a smart water containing a half concentration

of Mg2+ (RC1). Increasing temperature to 85°C when smart water

has double Ca2+ concentration (RC4) is a wrose scenario than

using 25°C with an smart water contains a half concentration

of Ca2+ (RC3). The fuel consumption using high temperature

could be replaced chemically by controlling the divalent cations

concentration. The fuel consumption could be more feasible

when controlling the water chemistry. The good example for that

is RC3 when lowering the Ca2+ to the half and also (RC1) when

lowering the Mg2+ to the half. Applying ambient temperature

with reducing Ca2+concentration to a half provided a higher oil

recovery among all the other scenarios (60% of OOIP). Table 3

shows the summary of the results.

Conclusion

Increasing the temperature of the injected water reduces the

viscosity contrast between oil and water in the heated region.

This can improve the sweep efficiency. Heating the oil using

hot water could reduce the oil viscosity and in turn increase oil

recovery.

Hot water flooding may also increase the economic life of

individual wells by as much as a factor of two. Controlling the

chemistry of water could provide a better solution for increased

heavy oil recovery instead of increasing the injected water

temperature, that could lower the energy required to move the

heavy oil from the heavy oil reservoirs in general and in this

work for the eastern Kansas oil reservoirs. The conclusions can

be drawn as follows:

i. The adsorption of the organic material in heavy crude

oil on the sandstone decreased because of the rock became

too water-wet for observing smart water flooding effect when

the divalent cations presented in a higher concentration.

ii. Heating could reduce the oil viscosity, interfacial

tension, and residual oil saturation which leads to potentially

higher recovery factor. Yet, controlling the chemistry of water

(especially divalent cations) could improve oil recovery

instead of increasing the injected water temperature.

Increasing temperature with tune water concentration

providing a greater heavy crude oil recovery.

Acknowledgement

The authors would like to express their grateful acknowledge

to Colt Energy Company. The authors thank the Higher Committee

for Education Development in Iraq and the Iraqi Ministry of Oil/

Missan Oil Company for their permission to present this paper.

The authors would like to express their grateful acknowledge

for Sandia National Laboratories is a multimission laboratory

managed and operated by National Technology and Engineering

Solutions of Sandia, LLC., a wholly owned subsidiary of

Honeywell International, Inc., for the U.S. Department of Energy’s

National Nuclear Security Administration under contract DE-NA-

0003525

For more articles in Open Access Journal of

Engineering Technology please click on:

Comments

Post a Comment