Juniper publishers Production of Bisphenol A (BPA) By Green Technology

Juniper Publishers - Open Access Journal of Engineering

Technology

Authored by : Ibrahim Altuwair

Abstract

The literatures and researches show that the reaction

between phenol and acetone is too slow in the absence of catalyst, but

it proceeds with formation of Bisphenol A (BPA) in the presence of

acidic catalyst or any strong acid [1].

Although the BPA formation depends on the molar ratio of reactants

(acetone and phenol), using a different solvents or catalysts will not

deny the effect of the BPA on human health. It is only enhancing the

reaction ratio between phenol and acetone and improves the selectivity.

There are different catalysts and solvents have been tested and their

effects on the process and BPA yields were evaluated. However, as the

reaction proceeded to increase the water concentration, the inhibition

effect of water reduces the reaction rate and gives low yield. This will

not eliminate the impacts of BPA directly or indirectly on human

health, it is only increased the quality of the product.

Keywords: Bisphenol A; Process; Reaction; Acetone; Catalyst; Concentration

Abbreviations: DCM: Dichloromethane; DOE: Design Of Experiment; PTSA : P Toluene Sulfonic Acid; DVB: Divinyl Benzene; SCF: Supercritical

Introduction

Bisphenol A production process

The aim of the chapter is to give an overview of the BPA production methods.

Preparation of Bisphenol A

The BPA synthesis including mechanisms, possible reactions, by-products, and order of reaction.

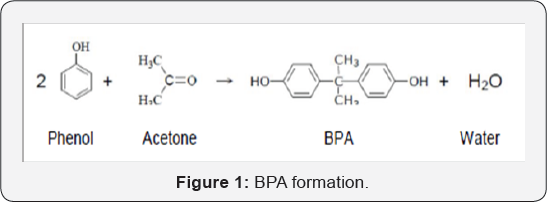

The acid catalyzed condensation of acetone with two moles

of phenol is the first process for forming BPA, (Figure 1).

The heat of reaction, for reagents and products in

their natural physical state at 25 °C, is calculated from heats of

formation as 19kcal/mol and a molar ration of 1:2 acetone to phenol, is

considered in the first stage of the research, in the presence of

concentrated hydrochloric acid at room temperature. There was a claim of

the present of small amount of water (10%) or less in the reaction

mixture increases the reaction rate of the mixture catalyzed by

hydrochloric acid [2].

Others suggest that processing the reaction by ion-exchange resin

(sulfonic acid) modified with alkyl-SH groups enhance the reaction and

decrease the amount of water 5% by weight in the mixture which decreases

the yield

of BPA. However, it was suggested by Jerabek et al. that to reduce the

effect of water, dehydration by various water-binding agents (such as

Calcium Chloride or phenyl acetate) or by azeotropic distillation can be

used.

This reaction proceeds with an electrophilic attack

of the proton from the acidic catalyst on the molecule of acetone.

During this step, producing by-products or “impurities” might change the

mechanism of the reaction by produce undesirable products as a result

of acetone - acetone reaction or Dimerization. Thus, Mesityl oxide is

formed and increasing the number of impurities that lead to further

phenolic reaction and the process becomes more complicated. Therefore

more effects on human health are expected due to phenolic impacts.

The most industrially used processes for making BPA

in the United States and Western Europe are the acetone-phenol Process,

There are different methods of producing Bisphenol A.

Conventional Methods

This method based on the type of the catalyst and

solvent. It is also called Hydrogen Chloride-catalyzed process. The

first production of BPA was made by Russian scientist, Dianin, in 1891.

He used Hydrochloric acid to accelerate the reaction since it is hard to

form BPA without strong acid. However, the process of obtaining BPA is

also depending on the phenol to ketone (acetone) reaction ratio. Thus,

there will be excessive phenol, approximately a ratio of (3-30):1 to

ensure the reaction is processed (WO 2005/030687, 2005). Although the

reaction gives high efficiency, the conventional methods of BPA

production does not provide approximately high selectivity of the

reaction of phenol with acetone and the required purity of the desired

product. It also appeared that it is impossible to achieve the

equilibrium state for some by-product of the process therefore the

process cannot be performed for long time without production loss. In

addition, because of the low concentration of BPA, high energy

consumption will be resulting from the process.

Alternative Methods

There are alternative methods to produce BPA by using

different catalysts with/without promoters. This method is also known

as the resin-catalyzed process. It gives better results in terms of

selectivity, and purity of product. One of the catalyst that been used

such as exchanger resin also improves the production of BPA. In

addition, there are other catalysts have been used and modified to

increase the BPA concentration and improve the phenol and acetone

reaction, for instance, sulfonated ion exchange resin, DVB divinyl

benzene, and polystyrene. Although the formation of BPA is improving

continuously, still there is no answer for the variation in ratio of

phenol to acetone.

Parameters

The selection of parameters depends on the specific

compound. There are several important parameters need to be taking into

account during the process:

1) Temperature

2) Time

3) Catalyst

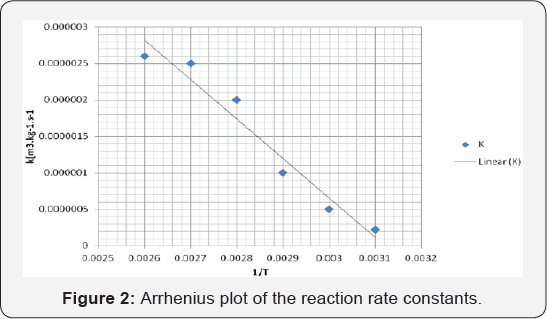

According to Arrhenius equation, the results obtained

were temperature dependence, for the water adsorption coefficient KW.

For the adsorption coefficient of acetone and phenol increased with the

temperature, although, the rate constant of reaction is increased with

temperature, the energy of between acetone and phenol is weaker (Figure 2).

K = 1470 Exp (-59900/RT) [m3kg-1s-1]

This showed that higher energy is needed to complete the formation of BPA due to the slow processing mixture.

Experimental Section

Experimental Procedures

P-Toluene sulfonic acid, acetone, and phenol were

purchased from Sigma-Aldrich Company. An appropriate amount of an

aqueous solution of chloroform was added to the solution at room

temperature. Synthesis of bisphenol A(BPA) was carried out in the liquid

phase under atmospheric pressure and 600C in 1000ml two-neck round

bottom flask equipped with a condenser and a magnetic stirrer. An 8.6g

of PTSA catalyst put into the reactor with 23.5g of phenol. Then, 2.9g

of acetone was added by a micro- syringe to start the bisphenol a

synthesis. Yield was determined by a column chromatography. Furthermore,

vacuuming the sample was applied after separation process to purify the

final product from the residual solvents. Weights were measured before

and after evaporation.

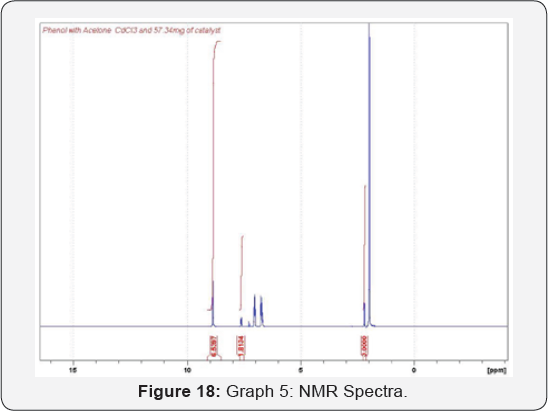

Characterization: Bisphenol A monomer

synthesis from the condensation reaction of phenol with acetone will be

analyzed by using Column Chromatography, NMR, GC-MS techniques.

Spectroscopic analysis showed that BPA monomer was present in the

product although significant amounts of compound formed during the

reaction and residual starting material were still present.

After sampling and cooling down the samples at 0 °C,

evaporation was applied by using rotary evaporator for 10-20 minutes at

40-60 °C . HNMR spectrum at 400MHZ was measured by a Bruker DMX500 with

the following condition; Spinning rate 5KHZ, Constant time 1.75msec,

interval 4sec, accumulation 500 times, and glycine as an external

standard of chemical shift. Before the measurement, the sample was

cooled at

-20 °C .

Materials and equipments: Phenol and acetone

as the main reactants of reaction brought from Sigma-Aldrich Company

P-toluene sulfonic acid-PTSA is available in the chemistry lab with

chloroform, Methanol, Dichloromethane DCM, acetonenitrile, (CDCl3, DMSO were used as deuterated solvents for NMR) Silica gel and Sand were also available in the lab.

250 & 1000ml two neck round bottom flask were

used, rotary evaporator R-114, water bath B-480&B-490RE Buchi,

condenser, thermometer.

Process Selection: Condensation of phenol with acetone in the presence of p-Toluene sulfonic acid (PTSA) as a catalyst.

Process Description: Acetone and excess phenol

are reacted at a temperature of 600C and atmosphere pressure by

condensation in p-Toluene Sulfonic Acid catalyzed reactor system to

produce p, p-bisphenol A, water and various by-products are also formed

in the reaction process. The crude distillation or chromatography column

helps to remove water and unreacted acetone from the reactor effluent [3].

Acetone and un reacted materials will be sent to rotary evaporation

process at 50-60 °C for more purification then mother liquor from

purification system is cooled down at -20.

Equipments Used:

1) Reactor

2) Oil bath

3) Condenser

4) Heater

5) Chromatography Column (CC)

6) Rotary Evaporator

Description

A. Components of a control System

The system is divided into the following components:

1) Process

2) Measuring element

3) Controller

B. Controlling System Used:

1) Temperature Control

2) Stirring control

3) Pressure Control

Temperature Control: It is desired to maintain

the temperature in the reactor by using a controller. If the measured

temperature differs from the desired temperature, the controller senses

the changes and modify at the required temperature.

Stirrer control: Stirring can be control by

using magnetic stirrer .In this experiment, IEC Magnetic stirrer was

used with CAT No.: CH2090-001 STIR Input: 220/240V.AC.50/60Hz.4AMP.

Pressure control: The pressure maintains at the atmospheric pressure. However, low pressure was used for some processes [4,5].

Preparation Method: The experiment carried out

in the chemistry lab based on the reaction of phenol- acetone reaction

and also the reaction will be tested in different ways. Firstly, the

reaction of acetone and phenol will be carried out. Secondly, the

homogeneous catalyst will be added. Thirdly, the reaction will be

processed in the presence of supercritical carbon dioxide, scCO2. The report will cover the first and second parts.

The main goal of the project is to use supercritical

carbon dioxide as a reaction medium for the production of BPA and also

for separation purposes to remove undesired products easily Minimizing

the effect of the undesired products on the BPA formation by using SCF

will be another target for the study as an advantage of using green

technology for BPA production and reduce the chemicals that emitted into

the atmosphere and polluted the environment. This technique will be

applied after synthesizing BPA by different methods to investigate and

evaluate their results with/without using ScCO2 technology.

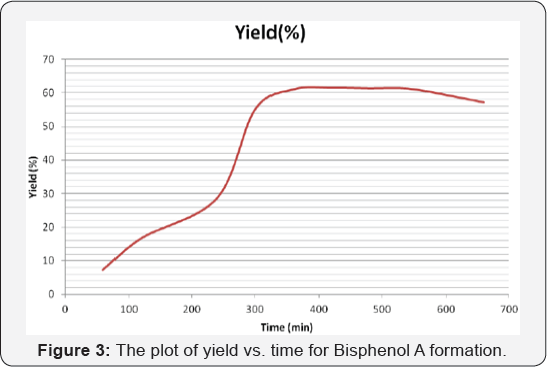

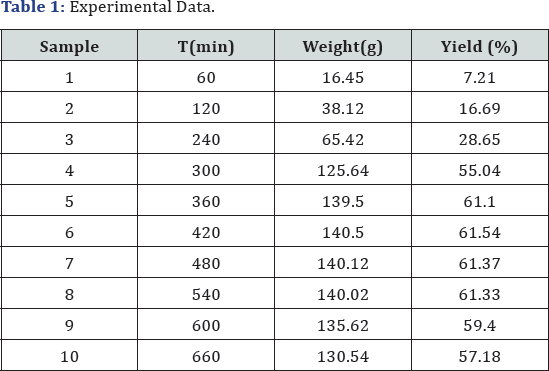

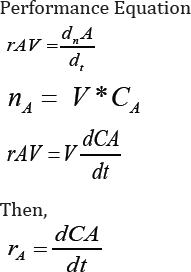

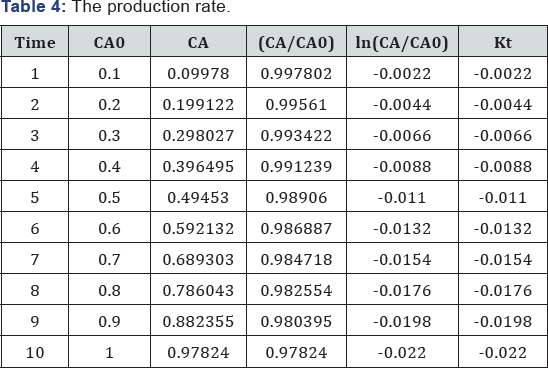

Experimental results and discussion: In order

to understand the reaction mechanism, several experiments were conducted

in the chemistry lab. These experiments were carried out at 60-800C for

all over variables, such as concentration of catalyst and reactants

fixed at maximum yield level. At the end of the experiment, the reaction

mixture was cooled down at room temperature and then stored at 20 after

dried and weighed. The

yield of the reaction mixture was calculated for each experiment. The

plot of yield vs. time is shown in Figure 3.

X = 1 - (1 + 0/03t )-2/0

Where, X: is fraction conversion of limiting component (mol/ mol) (Table 1).

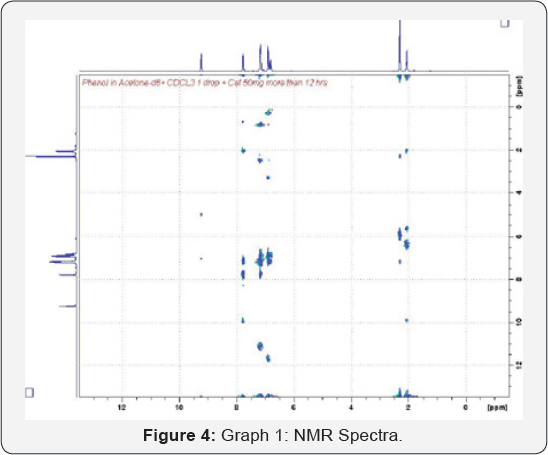

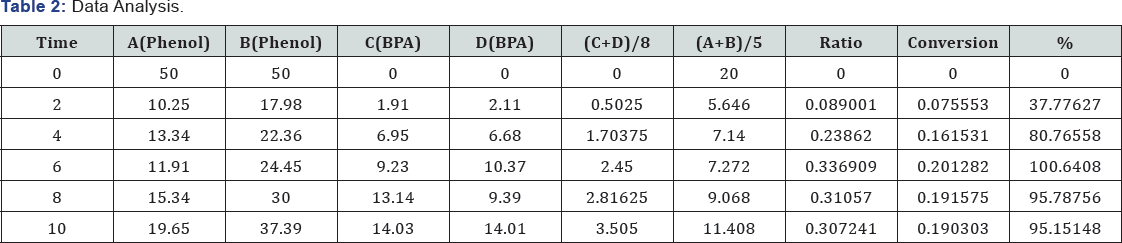

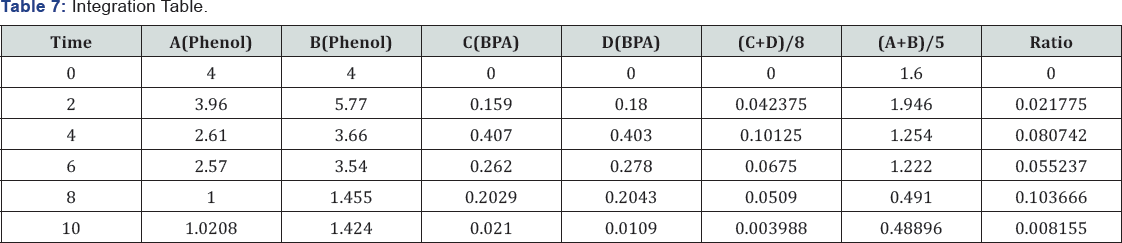

The graph is in a good agreement with literature data, this plot was generated based on experimental data (Figure 4) (Table 2).

Conversion %= R/(1+2R)

R: Ratio

Ratio= F / G

G: (A + B ) / 5

F: (C + D ) / 8

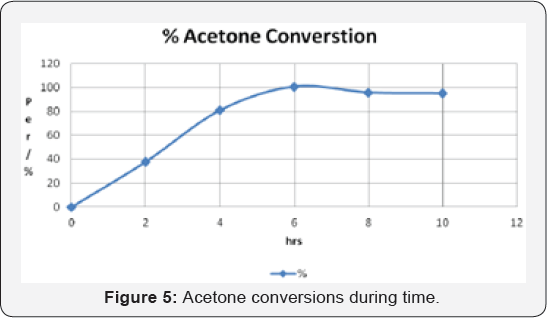

(Figure 5)

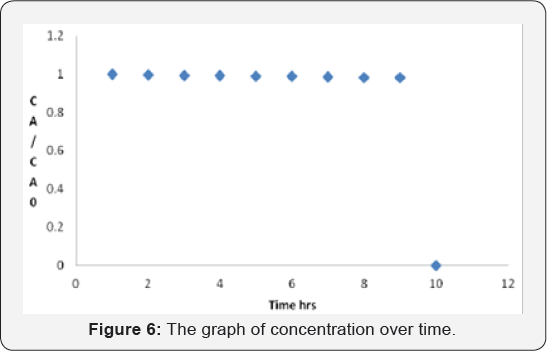

Analysis

The samples were analyzed by HNMR (Gyro and Flip

Machines). Gyro system was used to analyze the structure of the product

where flip was used for kinetic reaction purpose. All procedures and

results of the analysis are described in the following sections. The

graph shows the total acetone converted to product and time needed for

completion. It is very clear that after 6 hours of reaction, the whole

acetone converted to products.

Design of Experiment (DOE)

The following section will be focus on the

experimental design to investigate and evaluate the individual and

interaction effect. Using different techniques to deal with noise in an

experiment, and make a good decision for the chemical process. To design

an experiment by using engineering method or program, the following

steps need to be investigated:

1) Response Variables

2) Factors

3) Randomization

4) Repetition and Replication

Response Variables: Response Variables are the

variables that measured and the object of the characterization or

optimization (Y's). However, defining the response will be the hardest

part to design an experiment. To solve this problem, several questions

have to be answer such as:

a. How will the results be analyzed

b. How good is the measurement system?

c. What are the baseline mean and standard deviation?

Factors: They are variables which controlled

or varied in a systematic way during the experiment. These two steps are

important to design the experiment and evaluate or investigate the

factors effect on the process.

The purpose of using an experimental design is to

deal with different factors and make a good decision for an optimal

production process. Before starting the design of experiment DOE,

pre-experimental plan is recommended.

a. Experimental Design Procedures

Planning: Before starting the computer

program, pre- experimental planning needs to be done. t\The preparation

require before beginning experimentation depends on your problem. For

example, you need to determine what influence factors are, what

processing condition influence, thus careful planning can help to avoid

problem that can occur during the execution of the experimental plan.

Processing Characterization (Screening): In

many process development and manufacturing applications, potentially

influential variables are numerous. Screening reduces the number of

variables by identifying the key variables that affect product quality.

This reduction allows focusing on the really important variables.

Screening may also suggest the best or optimal setting for these

factors. Then you can use optimization methods to determine the best

settings and define the nature of the curvature. Screening test by

running a relatively small number of tests to isolate the most important

factors.

Optimization: (optimize a process/product):

The method of optimization helps to determine the best settings and

define the nature of the curvature. The optimal values for experimental

factors depend on the process objectives. The objective of this

experimental is to reduce by-products and maximize the BPA Yield.

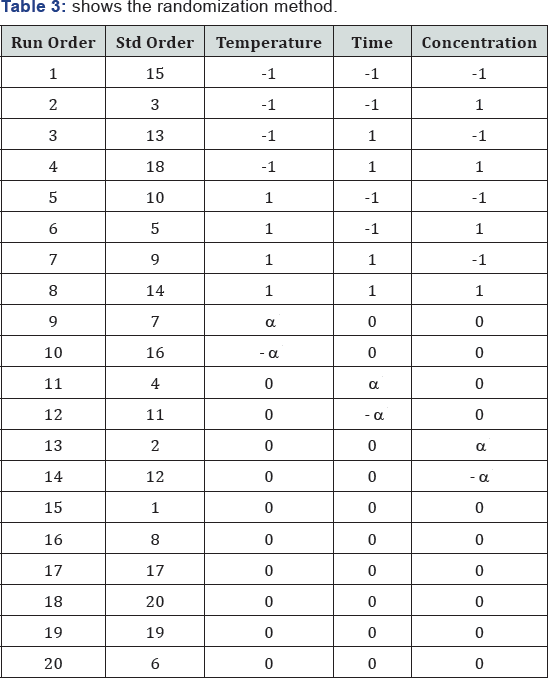

Randomization: It can be done in many ways

a. Run the treatment combination in random order

b. Assign experimental units to the treatment combinations randomly

c. The advantage of randomization is to average out

the effect of the extraneous factors (called noise) that may be present

but were not controlled or measured during the experiment.

d. Spread the effects of the noise across all runs

e. These extraneous factors (noise) cause unexplained variation in the response variable (Yield).

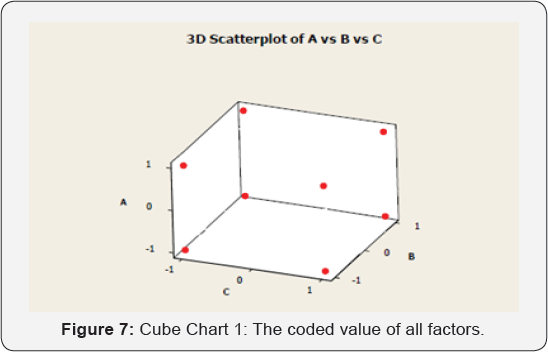

Minitab Program

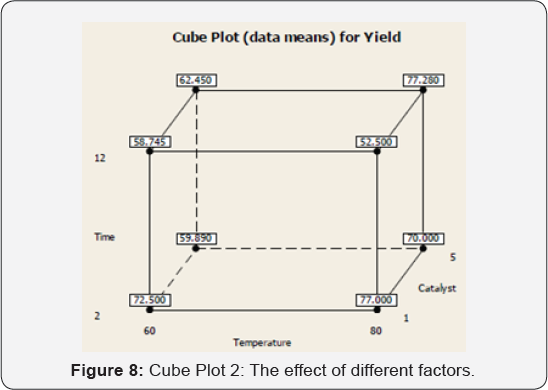

The below cube chart shows the coded value of all factors from high to low values (1to-1) (Figure 7,8).

The Cube Chart, the effect of different factors can be calculated by applying the following equation:

Effect = [(+Y / n ) - (-Y / n )]

Interaction plot

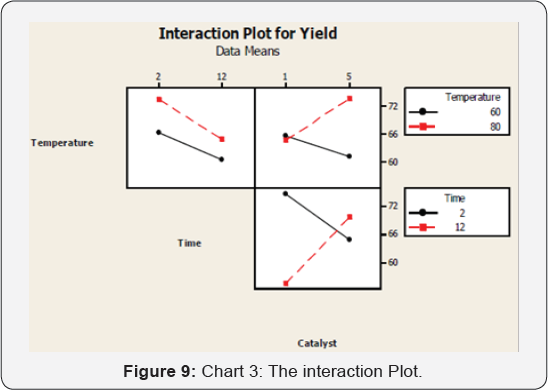

The following graphs show the interaction effect of

the different parameters on the process. The interaction between

catalyst and time has the greatest or significant effect on the process

followed by the interaction effect of catalyst and temperature then time

and temperature interaction effect.

By using the Minitab Programm, it is easy to evaluate

the significant factors with significant effects on the reaction

process and eliminate all factors without real effect on the process.

Also the program minimize the time that will be spent during the

reaction and focus only on the significant factors which will save time

and money (Figure 9).

Results and Discussion

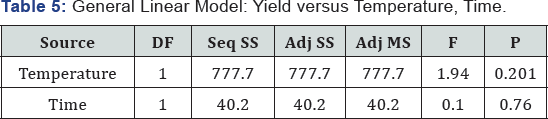

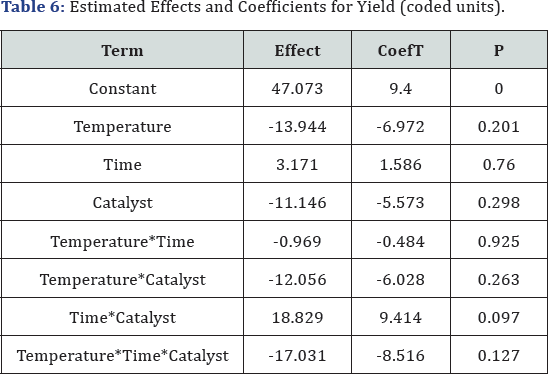

General linear model: Yield versus temperature, time (Table 5)

Factorial fit: Yield versus temperature, time, catalyst (Table

6) : Estimated Effects and Coefficients for Yield (coded units)

Al these values demonstrate the interaction effects

on the process such as Temperature and catalyst interaction that have

significant affects by high effect value and lowest P-value.

Evaluation

The mechanism of bisphenol reaction from industrial

starting material was studied. The obtained yield -time relationship was

obtained .It was found that at about 62% can be obtained after 6 hours

of reaction.

The experimental design detects the effects of

different factors on the process. In addition, the experimental data

shows the reaction rate of the starting materials and final products

which is in agreement with the HNMR spectra results even though there

were some experimental errors due to the equipments and measurement

errors. In addition, designing the experiment by DOE presents the

experiment by engineering way and save time and money for future

research.

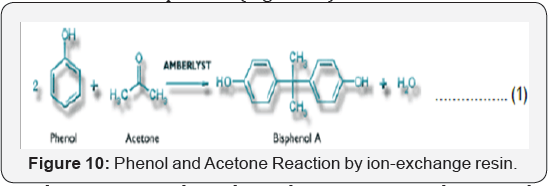

Drawbacks

Bisphenol A-BPA production process is continuously

improved by different ways even by manipulating parameters. However,

there's no answer to stoichiometric ration acetone to phenol variation

from 1-2 to 1-10 or 30, which add extra processing required during

purification. Thus, the reaction becomes more complicated (Figure 10).

The reaction is the industrial reaction to produce

BPA by using ion exchange resin. The Reaction shows that swollen ion

exchange resin with SO3H group attacks the aromatic ring to form BPA. Firstly, SO3H

group will react with carbonyl group (acetone) by less than completing

proton H+ and then acetone will react with phenol to give the final

product of BPA, the two aromatic rings shown on the BPA structure

describe the need of excessive phenol to react with one acetone in order

to produce BPA and water. However, producing water decreases the

catalytic activity of the resin. As water spreads towards the outlet,

the acetone conversion decreases [6].

This accumulation of water prevents a long-term

operation of the process; therefore, to stabilize the operation process,

water must be removed. Producing water during the reaction, slow down

the reaction and decrease the concentration of the product.

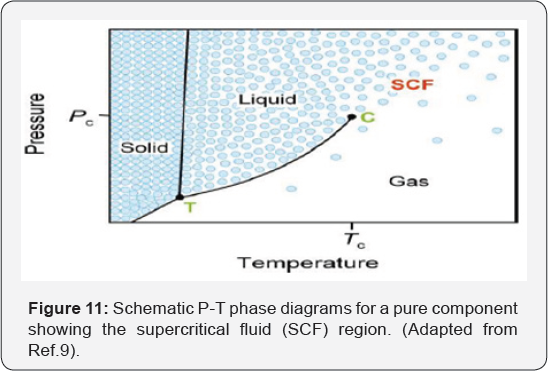

Basics of Supercritical Fluids

Supercritical fluid (SCF)

The triple point (T) and critical point (C) are

marked. The blue circle represents the variation in density of the

substance in the different regions of the phase diagram. Note that the

density varies continuously between the liquid state and the gas state,

providing the liquid-gas equilibrium (Figure 11).

Three different phases of the compound-solid, liquid

and gas are also shown. With an increase in temperature and pressure,

there comes a point when the compound shows intermediate properties

between those of a pure liquid and a pure gas that is the critical

point. The region beyond that critical point is the supercritical fluid.

Definition

What is supercritical fluids?: When the

temperature and pressure of a one-component fluid exceed its critical

temperature and pressure, it is said to be supercritical fluids. It is

neither liquid, nor gas as shown in the diagram and that give no any

clue to predict the properties of supercritical fluids (SCF). Therefore,

supercritical fluids are influencing the chemical processes in many

ways. They can be used as solvents since they have unique properties to

become as liquids and as gases together Furthermore, these properties

offer distinct advantages such as:

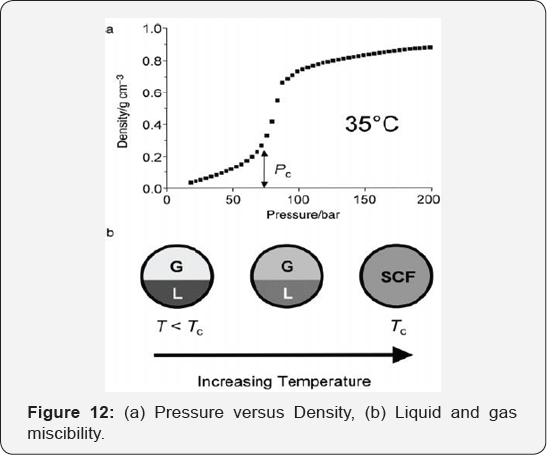

Gas-Expanded liquids (GXLs)

A Gas-expanded liquid (GXL) is mixed solvent composed

of a compressible gas such as carbon dioxide or ethane dissolved in an

organic solvent. In other words, it is the ability of the gas to expand

the liquid (solvent) and improve the physical and chemical properties of

the liquid (Figure 3b).

It is considered a magical chemical due to their unique properties. As

Jessop's group mentioned, (GXLs) are the promising alternative media for

performing synthesis, and separation [7] (Figure 12).

Figure 12a Graph showing the variation in density for pure CO2 at 35 °C. At this temperature (i.e., close to Tc for CO2)

there is a rapid but continuous increase in density near the critical

pressure (Pc). (b) Schematic representation of the change from

liquid+gas equilibrium (T

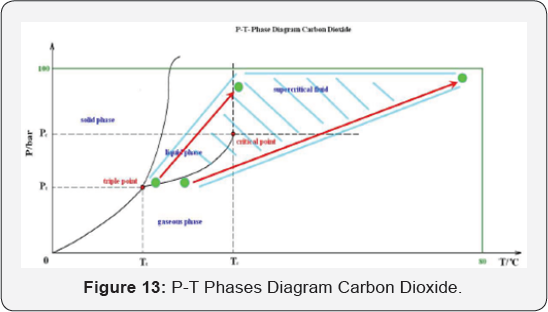

Supercritical carbon dioxide (SCCO2)

Supercritical carbon dioxide (SCCO2),at (Tc=304.1K, Pc=7.38MPa),

is the promising green solvent due to it is unique

property and behavior such as non-flammable, inexpensive, and

environmentally friendly and safe. It is also available abundantly. Many

researchers have shown that carbon dioxide has a high potential as a

solvent for many organic compounds and widely used for practical

application [8] (Figure 13).

This diagram shows the P-T phase diagram with the region of supercritical Carbon dioxide properties (Tc=304.1K, Pc=7.38MPa).

Applications of supercritical carbon dioxide: The

application of supercritical carbon dioxide (scCO2) as a

solvent has been on the rise. This is because of its low toxicity and

its usage in compound extraction. Further, it has a higher stability for

the different process reactions and need low temperatures for any

process to compare with other solvents [9]. Perhaps the most common use of supercritical carbon dioxide scCO2

is in the coffee industry. In addition, the application of

supercritical carbon dioxide has found its way into the pharmaceutical

industry. It is used in the production of micro-and nano-scale particles

[1].

Polymerization is another area that makes use of supercritical carbon

dioxide. It has proved to be a good nonpolar solvent for organic

compounds such as alkanes, alkenes, aromatics, and alcohols which can

easily dissolve in supercritical carbon dioxide. It is seen that polar

molecules such as sugars and other inorganic salts are insoluble but by

increasing the pressure of supercritical fluid, the dissolving power can

be improved [8].

Many studies noted that advantages of supercritical carbon dioxide are

attracting industries due to that they are inexpensive, non-toxic, can

be recycled, and has easily accessible critical conditions. Also,

supercritical carbon dioxide scCO2 processing of polymer uses

the liquid-like densities and gas-like mass transfer properties of

dense gases (DGs) to provide more controlled and more efficient methods

of polymers preparation. Also provides an environmentally benign method

for creating polymer compared with conventional processing that increase

the environmental threat by emitting Volatile Organic Compounds VOC's

and other polluted compounds into the atmosphere.

Supercritical fluids applications:

a. Supercritical Extraction

b. Particle formation

1. Particles from Gas-Saturated Solution (PGSS)

2. Gas Anti solvent (GAS)

3. Precipitation with Compressed Ant solvent (PCA)

4. Solution-Enhanced Dispersion by Supercritical Fluids (SEDS)

5. Depressurization of an Expanded Liquid Organic Solution (DELOS).

c. Supercritical Fluid Chromatography

d. Separations and crystallization

Synthesis and processing: The review focuses on recent advance in polymer synthesis and processing using liquid and supercritical carbon dioxide scCO2.

The synthetic techniques discussed include homogeneous solution

polymerization and heterogeneous and the variable solvents strength

associated with supercritical fluids have been used in areas such as

polymer fractionation and polymer extraction. Furthermore, the unique

physical properties associated with supercritical fluids give rise to a

range of possibilities for the chemical materials. Not only in polymer

science but also in organic synthesis, heterogeneous and homogeneous

catalysts. In the case supercritical carbon dioxide (SCCO2), there are chemical, environmental, and economic benefits that will be captured from its use as a solvent.

In addition, supercritical carbon dioxide technology has several advantages over conventional solvents as a reaction media [3].

The unique property of supercritical fluids observed from different SCF

experiments maybe used to manipulate chemical reactions to make them

more efficient or specific. In addition, SCF has a great miscibility

which might change heterogeneous reactions and become homogenous

reactions and the yield can be greatly improved [3]. Furthermore, it is stated that using scCO2 as a reaction media will change the properties of the reaction and enhance the reaction rate as well as the yield.

Separation

Beside the well-known environmental aspects of supercritical carbon dioxide (SCCO2),

it is also advantageous in the separation process as solvent due to its

preferable critical properties (Tc=304.1K, Pc=7.38 MPa) [10].

Using supercritical fluid to separate mixture compounds is an

interesting technique due to not tend to leave any toxic residuals or

cause potential thermal degradation of the product [10].

On the other hand, conventional solvents where used for separation

purpose are environmentally dangerous and create chemical waste that

supporting the phenomenon of greenhouse gases such as volatile organic

solvents (VOC).

Extraction

Extraction by Supercritical Fluids gives clean and

efficient technique compared to other techniques .Extraction by

supercritical fluids (SFE) technologies will enable solutes to dissolve

in the supercritical carbon dioxide (scCO2) and precipitated

by reducing the pressure of the fluid phase. The supercritical carbon

dioxide is then expanded to remove the solutes, and the gas is recycled

for repeated use [3]. Decaffeinated coffee and hop extracts are good examples for the application of extraction by using supercritical CO2.

However, BPA solubility in supercritical carbon dioxide will play an

important role in the BPA extraction process since it is barely soluble

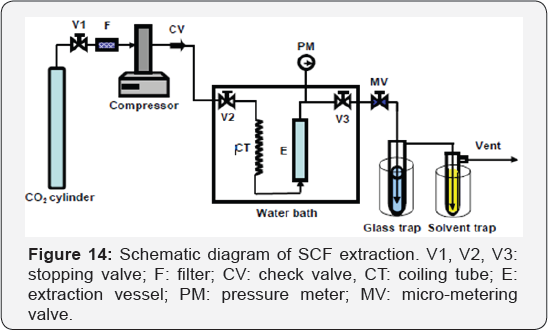

in SCCO2 and become easy to be extracted (Figure 14).

Supercritical fluids reaction

There is no attention been given to this topic to

classify the physical and chemical states of the supercritical carbon

dioxide as a reaction media to produce Bisphenol A-BPA. The unique

properties of supercritical fluids observed from different SFE

experiments used to make the reaction more efficient has been determined

to be used as a reaction media for BPA. In addition, a study made by

Chen et. al. showed that using scCO2 as a reaction media will

enhance the reaction rate and yield even though Liu group mentioned

that BPA was insoluble in supercritical CO2. Therefore, the study will focus on the chemical reaction of supercritical carbon dioxide.

Acetone

Acetone is an organic compound. Colourless, flammable liquid, and the simplest example of ketone with formula of (CH3)2CO.

As Gates et al mentioned, the reaction of acetone with phenol is too

slow in the absence of catalyst, but in the presence of acid resin, it

proceeds with the formation of BPA. From the theoretical viewpoint,

acetone with SCCO2, solubility of acetone in SCCO2 was increased with pressure and temperature [11].

Many papers showed that the solubility of acetone in supercritical

carbon dioxide increased based on the condition of pressure and

temperature [12].

However, diffusivity of the acetone affected by temperature, as the

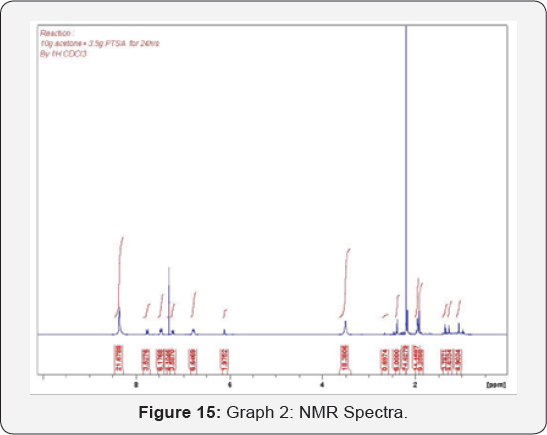

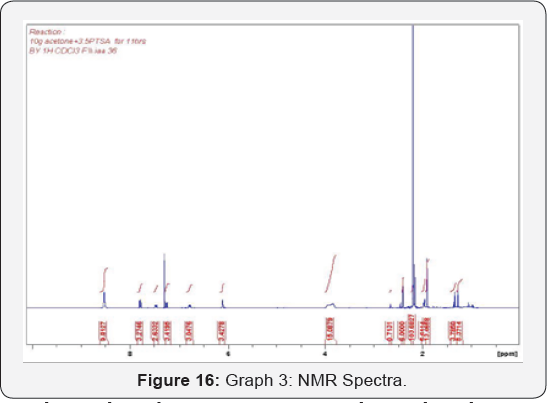

temperature increased the diffusion coefficient of acetone in SCCO2 increased at lower pressure [12]. Therefore, both temperature and pressure have significant effects on the diffusivity and solubility equilibrium [9]. Although acetone chemically instable, it is very obvious that acetone is soluble in SCCO2 under certain conditions which will help to get rid of the undesired products forms by AcetoneAcetone Reaction (Figure 15 & 16).

The analysis by NMR instrument shows that there are

several products made by the reaction with small percentage but the main

by-product is Mesityl Oxide which is detected by the analysis. It is an

important by-product in this reaction because of it's high reactivity

with other reactants. The study also focuses on the product as one of

the research goals.

Phenol

Phenol is a chemical compound consist of hydroxyl

group (OH) connected to an aromatic hydrocarbon group. Phenol has strong

acidity due to the aromatic ring. Its chemical formula is C6H5OH. The

chemical properties of phenol are unique due to the presence of hydroxyl

group and an aromatic ring which are complementary to each other in

facilitating both electrophilic and nucleophilic type of reaction (BPA

reaction is electrophilic) In addition, phenol has an extremely high

reactivity of its ring toward electrophilic substitution and assists its

acid catalyzed reaction with acetone leading to phenolic resin. Phenol

can be produced industrially with acetone by the cumene-to-phenol

process, there are more than 97% of phenol produced by this process

which reported by Hock and Lang. The cumene-to- phenol process was

developed on a commercial scale by Distillers

Co. in Great Britain and Hercules Powder Company in USA. The first

production plant was commenced in 1952 in Shawinigan, Canada. Today

several licensors offer their technology such as KBR or UOP. Although

all these processes use the principle of Hock synthesis, there are

differences in the design and operation of the reaction units and

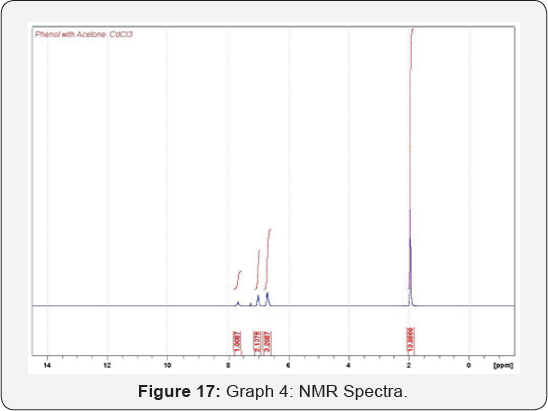

distillation unit (Figure 17 & 18).

The analysis made by NMR Spectrum for Phenol and

Acetone in the presence of catalyst which gives BPA. The Spectra showed

the development of the product while the reactant disappeared.

Solubility

Solubility is a crude property used for determining

the identity of an organic compound. It can be defined as the amount of

solute that dissolves in a given amount of solvent at a definite

temperature to yield a solution that is saturated in nature. However,

solubility is affected by several factors such as pressure, temperature,

and nature of solute and solvent [13].

Many studies on solubility in supercritical fluids have grown

drastically in recent years. This due to the large range of applications

of supercritical fluids in the fields of pharmaceutical, food,

environmental, and industrial process. The fact that the properties of

supercritical fluid can be varied from gas-like to liquid-like values by

changing the pressure makes it very interesting and useful. In

addition, solubility is the most important criterion affecting the

efficacy of most of the supercritical fluid processes [13].

It has a direct impact on the rate, yield, design, and economy of the

process, depending on the process of interest, high solubility or low

solubility may be desired, for instance, high solubility is required to

manufacture particle. In the case of BPA synthesis, solubility of

reagents in supercritical carbon dioxide is important to accelerate the

rate of reaction and enhance the reaction between acetone and phenol,

thus elimination of undesired products will be achieved [13].

Several studies were able to observe that an increase

in temperature of certain compounds could remove the gas-liquid

boundary. In the reaction of phenol with acetone, solubility improves as

the difference between solubility parameter of the solute and solvents

decrease [14].

The effect of Temperature and pressure will change the solubility

mixture. However, the problem of selectivity of the reaction of acetone

with phenol to form BPA has not been solved and the consumption of

phenol and acetone still differs from the stoichiometric data.

Manufacturing

The most industrially used process for making BPA are

acetone-phenol process, in homogenous and heterogeneous catalysts.

Considering the costs involved and the net advantages the heterogeneous

catalysts offers, the resin-catalyzed process is preferred and it has

been improved continuously. A process which considers reacting acetone

with very little excess phenol (1:4 or 1: 10) was reported by Azam and

his group [15].

The reaction of this process consists of two steps. In the first step,

the acetone is reacted with very little excess phenol in the presence of

a resin catalyst to convert 20 - 60 % of acetone. In the second step,

the reaction mixture from the first step will be reacted in the presence

of hydrochloric acid as a catalyst. Although there were different

processes using alternative feeds, by-products still come out with the

product mixture. Thus Purification is required.

Purification

The current process used to produce BPA influences

the composition of the mixture from the reactor. It is still expected to

contain phenol, acid catalyst (unless an acid ion- exchange resin is

used), water, BPA, by-products, and some acetone. For example, a crude

product stream consisted of 40% BPA, 36.2% o, p-isomer, 1.1% o,

o-isomer, 14.2% phenol, 3.5% Chroman, 0.05% flavan and 12% of undefined

materials. However, the composition of the BPA unusually available on

the market is 95% BPA, 3% Triphenol, 1%chromanes, less than 1% o,

p-isomer, and very small percentage of others. However, the BPA

production is continuously improving by using different purification

methods or even by changing small differences in the operating condition

which may be have considerable effect on the process. Evaporation and

Colum chromatography have been used in the current experiment for more

purification [16-18].

Purification processes: Bisphenol A separation

can be done in different ways such as evaporation, crystallization,

filtration, and centrifugation. Vacuum distillation was used in this

experiment to distill out the phenol at certain conditions. More

purification was applied on the crude BPA to remove all undesired

materials by using Colum chromatography.

Based upon these initial observations, plans were

made to use dry column chromatography on the crude reaction product (tar

residue) to separate the suspected phenol product from the reaction

mixture and unequivocally identify that material as phenol using TLC,

NMR, FTIR, and GC/MS techniques.

Colum chromatography: In column

chromatography, the stationary phase, a solid adsorbent, is placed in

vertical glass usually column. The mobile phase, a liquid, is added to

the top and flows down through the column by either gravity or external

pressure. Column chromatography is generally used as a purification

technique to isolated desired compounds from a mixture [19].

The mixture to be analyzed by column chromatography

is placed inside the top of the column. The liquid solvent (the eluent)

is passed through the column by gravity or by the application of the air

pressure. Because of the different components in the mixture have

different interactions with the stationary and mobile phases, they will

be carried along with the mobile phase to varying degrees and a

separation will be achieved. The elutants or individual components are

collected as the solvent drips from the bottom of the column. There are

two categories for column chromatography separation:

a. Gravity column chromatography, when the solvent is forced down the column by gravity.

b. Flash chromatography, when the solvent is forced down the column by positive air pressure.

Procedure for dry column chromatography of crude reaction product:

A solution of tar residue (crude product) from the reaction, dry silica

gel powder (column chromatography grade-250 mesh) until all of the

solution was absorbed into the silica powder which was then air-dried to

produce a free flowing powder containing crude reaction product. This

powder was added to the top of a dry column of silica gel (1” diameter

& 20” length) in preparation for preliminary cleanup of the reaction

mixture. The column was elute with a total amount of 100 ml dichloro

form methane (DCM) and methanol (meOH), producing an initial band of

product that eluted from the column and was collected in labelled beaker

1. After the DCM elution completed, the collected amount of product

evaporated immediately on a rotary evaporator to make sure that

sufficient product was isolated for unequivocal identification of the

phenol component. An estimate of the yield from the reaction was made at

that time; however, TLC analysis indicated the presence of the phenol

component (estimated by darkness intensity of product spot). Two

solvents mixture were tested:

1) Aceto nitrile CH3CN and Dichloromethane DCM CH2Cl2

2) MeOH and Dichloroformmethane DCM CH2Cl2

Up to this time, however, the isolation of phenol

component was only suspected from TLC evidence, not proven by

unequivocal means. Analysis of the reaction products using GC-MS and LC-

MS, confirmed the presence of phenol but NMR technique was used in this

reaction to detect the structure of bisphenol A and phenol as un

reacted compound (Figure 19) [20-23].

The absorbent: The absorbent used in the experiment is silica gel (SiO2) which is solid 130-400.

The solvent: The polarity of the solvent which

is passed through the column affects the relative rates at which

compounds move through the column. Polar solvents can be more

effectively compete with polar molecules of a mixture for the polar

sites on the adsorbent surface and will also better solvate the polar

constituents. Consequently, a highly polar solvent will move even highly

polar molecules rapidly through the column. If the solvent is too

polar, movement becomes too rapid, and little or no separation of the

components of the mixture will result, but if the solvent is not polar

enough, no compounds will elute from the column. Proper choice of an

eluting solvent is essential for better separation [24-26].

Sand: It was recommended to use sand in the column to enhance separation and stabilize the stationary phase in the column.

Thin-layer chromatography (TLC): It is a

method used by organic chemistry labs and the most common method. It is

generally used to analyze and determine the system for a column

chromatography separation.

Thin-layer Chromatography (TLC) analysis is to

determine the components present within the reaction mixture. TLC

analysis (multiple elutions using Methanol/Dichloromethane) indicates

that the reaction mixture isolated from the product contained a

multitude by its Rf value in comparison to the Rf value obtained for

authentic phenol. Short-wavelength UV light was used to visualize the

otherwise colorless spots on TLC, which appeared as a dark shadows

against a green fluorescent background. Authentic phenol was spotted

alongside the reaction product showing a spot exhibiting Rf identical

with that attribute to the phenol component in the reaction mixture. TLC

obtained for crude product isolated from reaction mixture showed a

sizeable spot coinciding in Rf with the Rf value exhibited by an

authentic phenol spot. Based upon these initial observations, plans were

made to use dry column chromatography on the crude reaction product

(tar residue) to separate the suspected phenol product from the reaction

mixture and unequivocally identify that material as phenol using TL [27].

Physical properties

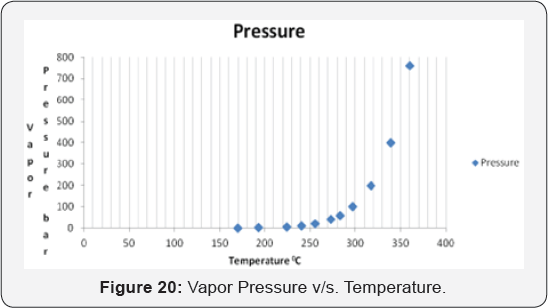

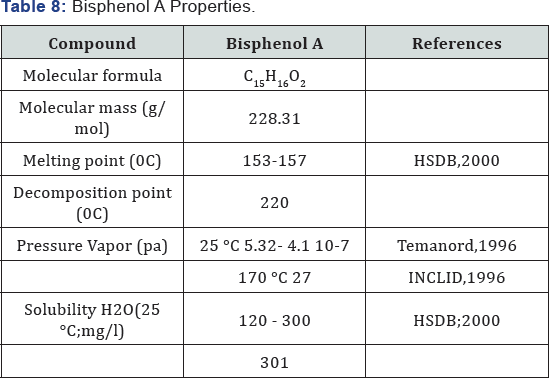

Bisphenol A is a white crystalline solid, appearing

like small white to light brown flakes or powder, with mild phenolic

odor, moderately high in water solubility (120mg/l at 25 °C). It is

specific gravity is given as 1.195 at 25 °C. It is vapor pressure is

(5.32*10'5pa m3mol-1. It is melt at 157 °C . It should be emphasized that the vapor pressure considerably increases at increasing temperature. Table 7: Bisphenol A Properties (Figure 20).

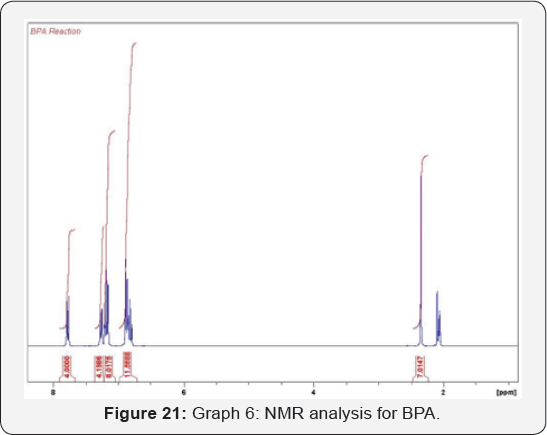

The graph shows the relationship between the vapor

pressure of BPA with temperature. The pressure will be increased with

the increasing temperature; therefore, the temperature needs to be as

low as possible. It is recommended that the preferable temperature for

process production ranged between 50-200 °C (Figure 21).

Apparatus

A liquid chromatography system consisting of binary

pump (Spectra Physics (SP), P2000 LC) with helium degassing kit was

used. The data-jet integrator was connected via Lab net to a personal

computer with SP Winner for Windows software. The fluorescence detector

was from Perkin Elmer (PE LS 40). The ultraviolet detector was from SP

(UV 2000), with scanning function on eluting peaks for the second and

third confirmation options [28]. High Pressure Liquid Chromatography (HPLC) will be used to analyze and identify the desired and undesired products.

Chromatography conditions

An injection system with a 50μL loop was used.

Fluorescence Detector. Settings: extraction wavelength, 225nm and

emission wavelength, 305nm.

Ultraviolet Detector, The wavelength was set at 225nm

(only for second confirmation option); scanning between 190 and 340nm

(third confirmation option).

Column, Length, 15nm; internal diameter, 4.6mm;

packing, 5μ Spherisorb ODS2. Elution Program for Gradient Method.

Gradient elution consisted of a 2-min isocratic elution with aceto

nitrile-water (30:70); an 18-min linear gradient to 80% aceto nitrile, a

3-min linear Gradient to 100% aceto nitrile, and a 2-min isocratic

elution at 100% aceto nitrile [29].

NMR

What is NMR?

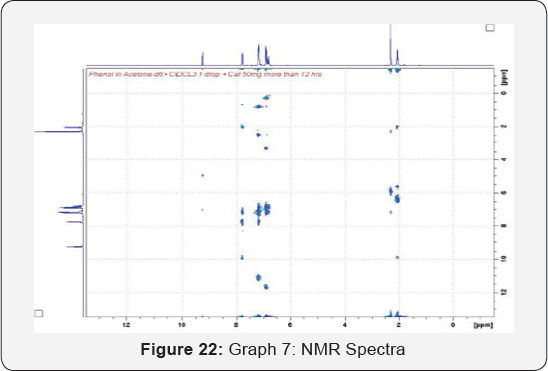

It is Nuclear magnetic resonance, or NMR as it is

abbreviated by scientists, is phenomenon which occurs when the nuclei of

certain atoms are immersed in a static magnetic field. Most of the

matter that can be examined with NMR is composed of molecules which are

composed of atoms (Figure 22 & 23) (Table 7).

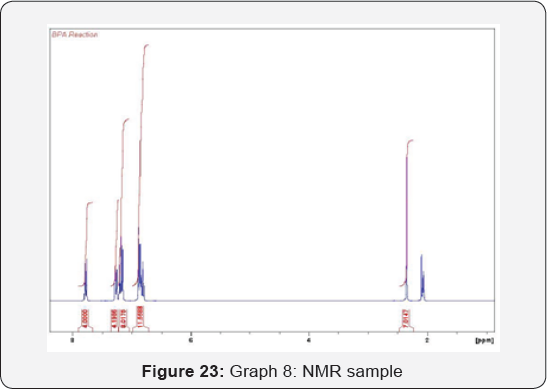

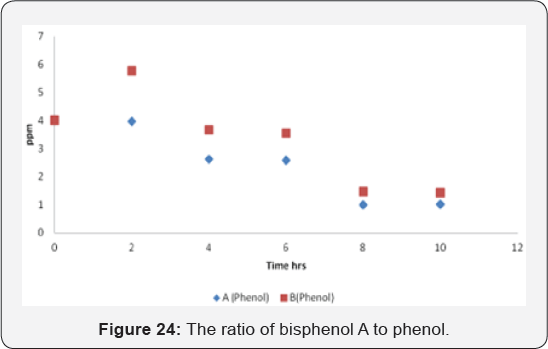

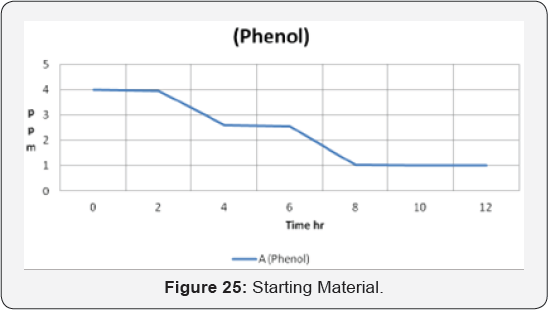

The graph presents the starting material (phenol)

disappearance through the reaction time. Phenol protons (phenol A &

Phenol B) decreased while the final product will appear slowly during

the reaction until BPA completely formed (Figure 24 & 25).

The curve shows the reaction of phenol during the reaction.

HNMR-Spectroscopy

Spectroscopy is the study ofthe interaction of

electromagnetic radiation with matter. Nuclear magnetic resonance

spectroscopy

is the use of the NMR phenomenon to study physical, chemical and

biological properties of matter. As a consequence, NMR spectroscopy

finds applications in several areas of science. NMR spectroscopy is

routinely used by chemists to study chemical structure using simple

one-dimensional techniques. Twodimensional techniques are used to

determine the structure of more complicated molecules. These techniques

are replacing X-ray crystallography for the determination of protein

structure also. Furthermore, the versatility of NMR makes it pervasive

in the sciences. This is just a basic principle necessary to begin using

NMR Spectroscopy. NMR Spectroscopy will be a useful technique to be

used to measure the amount of BPA produced [30].

The experiment will be carried out in the chemistry

lab to apply the reaction and measure all the factors, where other

techniques such as HNMR, CC, and TLC will be explained in the following

sections.

Reactor loading and set-up

1) Put on protective clothing, lab coat, goggles, and gloves. All the steps were performed in the fume hood.

2) Weigh the desired quantity of catalyst (10%) in a clean measuring dish.

3) Transfer the catalyst into the flask.

4) Weigh the desired quantities of phenol and acetone (4.7g or 23.5g of phenol and 0.58g or 2.90g of acetone).

5) Add the measured quantities of reagents to the reactor

6) Turn on cooling water to condenser

7) Turn on Magnetic stirrer

8) Turn on the heat and adjust the thermostat for the desired temperature.

NMR tube reaction

1) Weigh a clean, empty NMR tube.

2) Weigh 0.05g of catalyst in the NMR tube. To avoid transfer losses, the desired quantity was measured directly in the tube.

3) Prepare a mixture of acetone and phenol with ration of 1:2 acetone to phenol.

4) Take 40|il of the mixture with Pipette and put them into the tube.

5) Add 600|il of deuterated chloroform to the tube

6) Cover The NMR tube and seal carefully with para film.

7) Insert the tube in the appropriate spinner and adjust the depth using the sample depth gauge.

8) Turn on the air and position the tube in the magnet.

9) Lower the tube into the magnet by turning the air off.

10) Start the spinning air.

11) When the spinning rate reaches its set value, adjust lock power and lock gain.

12) Center and then lock signal.

13) Start heating the magnet by turning on the

heater, setting the temperature at 343K, and increase the air flow

through the magnet.

14) Once the temperature is reached, shim the field, and start the routine for data acquisition.

Reactor shut-down and clean up procedure

1) Put on protective clothing, lab coat, goggles, and gloves

2) Turn off the heater.

3) Turn off the magnetic stirrer.

4) Turn off the cooling water to the condenser

5) When reactor is at room temperature, remove the reactor from the C-Clamp.

6) Distill it out by Rotary evaporator

7) Take the weight of the sample

8) Put the sample in the fridge at -200C

9) Then take analyze the sample.

10) Wash flask, the stopper, and the thermometer with

acetone, then with water and soap, then with distilled water, and allow

them to dry.

11) Rinse thoroughly the sampling syringe with acetone to remove any residuals.

NMR tube reaction

1) Remove the tube from the magnet.

2) Turn off the heater, and set the temperature back to the room temperature value.

3) When the magnet cooled down, reduce the air flow through the magnet.

Summary

The review covers important aspects and present a new

way of producing a chemical/organic material, BPA, which is important

as the main feedstock for polycarbonate production. However, there are

gray areas among catalysts type that might be used during the reaction

with high efficiency. The paper presenting a solution of using

supercritical fluid as a green technology in order to produce bisphenol A

(BPA), which can be used as an essential part of polycarbonate

synthesis. To limit the use of conventional methods, new and reliable

methods have to be applied and by using supercritical fluid technology

to produce BPA as a high chemical scale production, many industrial

productions will be changed. Finally, supercritical carbon dioxide has

shown its applicability for food, pharmaceutical, medical, and chemical

processes. The work presented in this study focused on bisphenol a

processing and the purpose of this paper is to:

1) Identify new suitable catalysts for BPA formation

2) Find appropriate reaction conditions

3) Determine the reaction conditions that significantly influence the process and explain their influence.

The analysis of experimental design shows that the

interaction effect of temperature with catalyst has significant effects

on BPA yields. Furthermore, the interaction effect of temperature with

time has also a significant effect on the process but in the present of a

strong catalyst with the optimal operating conditions for maximum

yield. Whilst individual effects of time and concentration have minor

impacts on the process.

Future plan

The main part of the future work will be depend on

the mixture identification and impurities detection by using different

analysis techniques such as TLS, GC-MS, and NMR to confirm all undesired

products which formed by acetone-acetone reaction. Therefore,

supercritical carbon dioxide as a new technology to purify undesired

products associated with acetone reaction (Dimerization).

Appendix

A. Appendix: The NMR phenomenon

Nuclear Magnetic Resonance (NMR) spectroscopy is a

method of great interest and important for the study of chemical

substance. The use of pulsed Fourier transform methods with spectrum

accumulation made it possible to obtain high resolution spectra (Sander

and Hunter, 1993).

B. The chemical shift1

Resonance occurs at slightly different

frequencies for each type of proton, depending on its chemical binding

and position in a molecule. This variation is caused by the cloud of

electrons about each nucleus, which shields the nucleus against the

magnetic field, thus requiring a slightly lower value of v0to achieve

resonance than for a bare proton (Sanders and Hunter, 1993). Protons

attached to or near electronegative groups such as OH, OR, OCOR, COOR

and halogens experience a lower density of shielding electrons and

resonate at higher v0. Protons farther removed from such groups, as in

hydrocarbon chains, resonate at lower vO.These variations are called

chemical shifts and are commonly expressed in relation to the resonance

of tetra methyl silane (TMS) as zero of reference. The total range of

proton chemical shifts in organic compounds on the order of 10ppm.

For any nucleus, the separation of chemically shifted

resonances, expressed in Hz, are proportional to BO. When expressed in

ppm, as common, the chemical shifts are independent of BO. The

electronic screening of nuclei is actually anisotropic so that the

chemical shift is a directional quantity and depends on the orientation

of the molecule with respect to the direction of the magnetic field. In

solution, the motional

averaging produces an isotropic value of the chemical shift.

C. Nuclear coupling

Nuclei sufficiently removed from each other do not

feel the effects of the magnetic fields of the other nuclei. In this

case, the local magnetic field at each nucleus is essentially equal to

B0. If BO can be made very homogeneous over the sample, the width of the

resonance may be very small.

D. Direct dipole-dipole coupling

In most substances, protons contribute to local

fields and are sufficiently numerous to have a marked effect. The C

atoms also contribute to the local fields, but their natural abundance

is very small, therefore they do not have a visible effect.

E. Indirect nuclear coupling

Magnetic nuclei may transmit information to each

other concerning their spin states not only directly through space, but

also through the intervening covalent bonds. This is indirect or scalar

nuclear coupling, also known a J coupling. Rapid tumbling of the

molecule does not reduce this interaction to zero. If the nucleus has n

sufficiently close, equivalently coupled spin - % neighbors, its

resonance will be split into n+1 spin states of the neighboring group of

spin. Thus one neighboring spin splits the observed resonance to a

doublet, two produce a 1:2:1 triple, three a 1:3:3:1 quarter, and so on.

The strength of the coupling is denoted by a coupling constant J and is

expressed in Hz.

For more articles in Open Access Journal of

Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

Comments

Post a Comment