Manufacture Method of Forearm Prosthesis Combined Sockets for Complex Prosthetics-Juniper Publishers

Juniper Publishers-Open Access Journal of Engineering technology

Abstract

Background: The shape and dimensions of the

stump do not coincide, according to anatomical and physiological

considerations, with the shape of the inner surface of the socket. They

change during the operation of the prosthesis due to temperature, blood

pressure, intensity of the load, concomitant diseases.

Objective: Forearm stump of mans with age 40-55years. Reason for amputation is trauma.

Method: Develop designs of combined sockets

depending on the defect of the stump and its level with embedded covers

or elements dampening peak loads and measuring piston movements with

different sockets.

Results: Stump reciprocating movement in the prosthetic socket was reduced.

Conclusion: Embedded covers and elements

dampening peak loads allow to realize better feedback. Patients get one

more factor to use their prosthetic in daily life.

Keywords: Upper limb; Sockets; Manufacturing method; Results of practical prostheticIntroduction

When using a prosthesis, the covering tissues of the

stump experience stresses [1-3], which are the main cause of

inconvenience, pain and injury, reducing the positive effect of

rehabilitation [4-7]. The anatomical and functional features of the

forearm stump are characterized by a significant number of bone

protrusions, covered only by skin and small volume of soft tissues, so

there are few areas that can withstand the stresses arising from the

prosthesis use [8-11]. These features greatly complicate the optimal

distribution of pressure in the socket of the prosthesis and increase

the risk of traumatization of the skin. This is connected with a high

percentage of development of vices and diseases of the forearm stump

[12-16].

The situation is significantly complicated by the

already existing vices and stump diseases. It is known that besides the

congenital pathology and errors of the technique of amputation and

prosthetics, in a number of cases the development of vices and diseases

of the forearm stems is a consequence of the truncated limb adaptation

to the new conditions of functioning [17-20]. In the course of this

process, a number of morpho functional changes occur that are associated

with compensatory-adaptive reactions of the stump tissues to unrelated

loads, in particular, hypertrophy of the skin of the stump having a

reduced resistance to mechanical

stress and a pronounced atrophy of the subcutaneous fat. There are also

significant changes in blood circulation in the stump, which, on the one

hand, is associated with morphological changes in the walls of the

vessels that lead to their obliteration, and on the other hand, with a

significant decrease in muscle mass [21-26]. This leads to chronic

hypoxia of stump tissues and a decrease in their tolerance to stress.

And in the future, in the course of a prolonged load on the truncated

limb, the compensatory mechanisms fail and the pathological changes in

the tissues of the stump develop, manifested as vices and diseases [27].

This situation leads to the need for the use of

additive damping elements, especially for active prostheses of the upper

limbs. Over the long history of prosthetics, many attempts have been

made to use various softening materials-the lining of the inner surface

of the sleeve with soft skin, the embedded elements of felt, rubber,

leather, sponge, etc., but they did not provide sufficient cushioning

and protection of the tissue [28-31]. Their main disadvantage was the

absence of a reliable fixation of the prosthesis and, consequently, the

impossibility of eliminating the piston-like movements of the stump in

the socket.

At present, the most common method of forearm

prosthetics is the use of prostheses with full-contact sockets. Numerous

domestic and foreign studies on the properties of these types of

prostheses have shown their beneficial effect on the clinical and

functional state of the truncated limb [32-36].

It was found that a more even distribution of the load along

the surface of the stump promotes the normalization of the

function of the muscles of the truncated limb, and the activation

of blood circulation in the truncated segment. In addition, the

presence of a partial support on the butt end of the stump

improves the musculo-articular sensitivity of the stump, facilitates

the appearance of feedback or a “sense of contact with the object”

when used, especially prostheses with a traction control system

and working prostheses.

However, when using prostheses with full-contact sockets

made from sheet thermoplastics or layered plastics based on ortho

crylic resins, the skin of the stump is often traumatized by the rigid

wall of the receiving sleeve. This problem is most relevant for the

stump of the forearm.

Materials and Methods

10young and middle-aged patients (from 18 to 45 years old)

who underwent amputation due to injuries and who did not suffer

from any diseases of the musculoskeletal system were involved in

the survey. Patients had no limitation of mobility in the preserved

joints of the truncated limb, previously prosthetics, and trained in

the use of prostheses.

Three sockets types were made from 3mm high-pressure

polyethylene sheet for three versions: a standard design (type 1),

a full contact (type 2), and a composite sleeve with a 3-5mm thick

foamed thermoplastic sleeve (type 3). To work on the proposed

technology, a sheet of high-pressure 3mm thick polyethylene,

foamed thermoplastics 3-5mm thick, modules of prosthetic

forearms of the manufacturers of JSC RSC Energia, Ottobock.

Prostheses were preliminarily given out on a test sock for

1-2days, after which a preliminary assessment of the functionality

of the prosthesis and clinical examination of the stump was carried

out to exclude the influence on the research process of defects and

prosthetic errors.

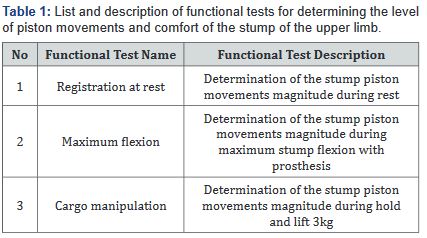

The survey protocol included a number of functional tests

(Table 1), to determine the level of piston movements of the

forearm stump with different designs of the receiving sleeves

during manipulation. To measure the pistoning used a ruler.

Projection of socket border during the phase lined on a stump.

After the movement the distance between socket border and the

rest line was measured.

In future work it is possible to use electronic system based on

RFID or potentiometer to get more accurate results.

One of the approaches to reducing unwanted loads on the

stump is to improve the construction and methods of socket

manufacturing, and the technology of its attachment to the stump.

This approach can be called conditionally direct, since it is about

improving the methods of direct contact of prostheses with the

human body. The main problem is that the shape of the surface

of the stump cannot coincide for anatomical and physiological

reasons with the shape of the inner surface of the socket. Moreover,

the shape and dimensions of the stump can change during the

operation of the prosthesis due to the influence of many factors

(temperature, blood pressure, intensity of the load, concomitant

diseases, such as diabetes, etc.).

There are two ways to solve the problem. Firstly, a digital

spatial scanning of the stump shape followed by the transformation

of the coordinates. Secondly-the development of receptacle

designs depending on the level of defect and stump defect and the

development of protective covers or embedded elements made

of foamed or gel-like materials that damp the painful peak loads,

thereby increasing the convenience of prosthesis using.

Studies to improve the interaction between the socket and the

stump have led to the development of fundamentally new designs

of combined full-contact, non-falling sockets for the forearm

prosthetic using softening inserts and elements of their foamed

thermoplastic materials and silicone compositions.

Experimental

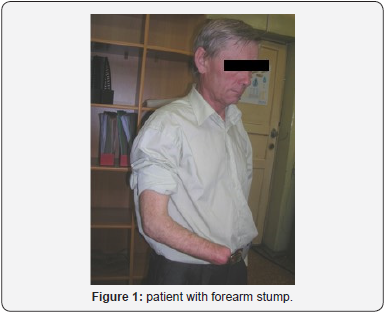

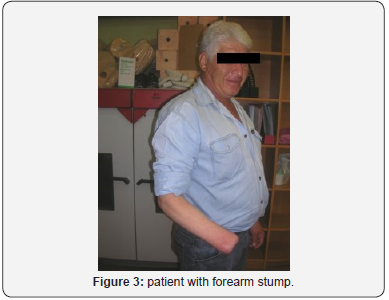

The form of the stump is complex-the presence of retracted

scars, clavate form or vice versa-a pronounced conical shape,

so it is difficult to achieve complete contact between the skin

integuments and the liner.

This problem for upper limb prostheses is not solved. For this

category of disabled people, proposed a prosthetic technique with

the use of a special design of a combined full contact non-dissolving

socket with an inner socket. Get it by foamed polyethylene or

pedilene, compensating for the bulb-shaped thickening due to

the thickness of the liner walls or the manufacture of special

longitudinal holes on the liner surface whose dimensions

corresponded to the thickening. As practice showed, the upper

opening was distal to the lower one.

The method of manufacturing this socket on a

club-shaped

stump is as follows: from a sheet of foamed thermoplastic

material (foam polyethylene, pedilene, etc.) 4mm thick, according

to the dimensions of the positive, cut out the workpiece. Then

placed the billet in an oven and kept at a temperature of 70-80

°C for 2-3minutes. The heated material became elastic and easily

subjected to blocking by positive. Then removed excess material

along the seam line and welded the seam together with a soldering iron.

The inner socket (cover) obtained from this was not removed

from the positive, but the socket was immediately blown from a

sheet of polyethylene 3mm thick heated to a temperature of 150-

160 °C. At the same time, welded the inner socket to the outer

socket. After cooling the complex socket tried on the patient.

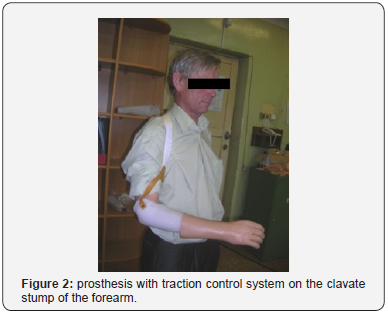

The combined complex full contact noncontiguous socket

made in this way was used without additional fastening in

functional cosmetic, with a traction control system and working

prostheses. The received internal cover provided softening of

impact loads and redistribution of pressure in a socket (Figures

1-4).

Second method of manufacturing a socket on a clubshaped stump

It includes using an additional special liner from a foamed

thermoplastic compensating the clavate thickening due to its

thickness. Cut the workpiece into a semicircular shape with a radius

of 30-50mm with thin edges 4-5mm in thickness. Superimposed

the preform heated to 70 °C on the positive with an inner cover in

the area of the wrist joint for alignment of the clavate thickening.

Then blocked the external socket of sheet polyethylene. According

to this technique, the inner socket captured only the lower third

of the forearm. In this design, the combined socket did not require

the manufacture of special holes in prostheses with a traction

control system. This design can be used in prosthetics with a

bioelectric control system, because in the locations of the sensors,

the elastic material is absent and does not reduce the level of the

signal from the muscular source.

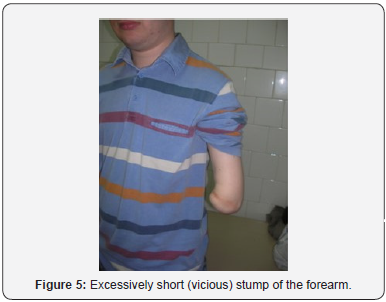

Used a similar technology in the manufacture of a socket for the long stump of the forearm

To ensure full contact between the stump and the socket

during the production of the negative on the short, conical and

cicatricial stump, the especially carefully performed modeling

in the region of the apices of the epicondyle and ulnar process

of the ulna. On the posterior and lateral surfaces of the positive

5-7mm, enlarged the sites corresponding to the protuberances

in the region of the ulnar process of the ulna and the condyles of

the shoulder. Made them elongated in the longitudinal direction,

taking into account a certain movement of the ulnar process and

a change in the position of the condyles of the shoulder relative to

soft tissues during movements in the elbow joint.

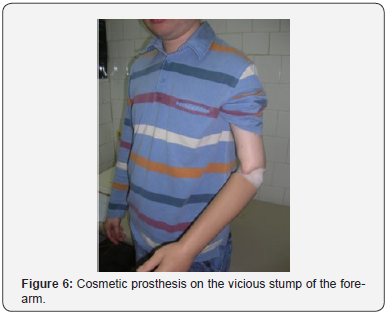

Then, hugging the shoulder from behind and above the

condyles, the first and third fingers simulated a semi-circular

pelots, and in the distal section of the negative-the palmar and back

pelots, corresponding to the elbow and radius bones, flattened

the negative along the entire length of the forearm in the sagittal

plane. Check the shape of the rear pelot, its width should be about

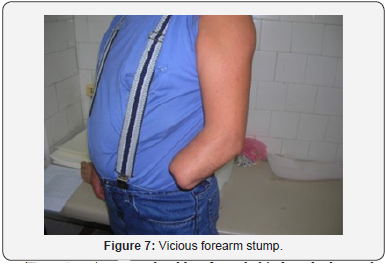

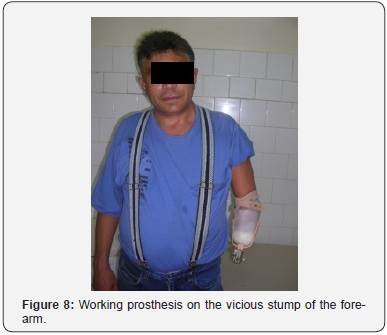

15mm (Figures 5-6). Depending on the area and location of the

stump scars, made sockets with embedded foamed polyethylene

or of silicone composition elements (Figures 7-8). Most often

with short forearm cults, observed an excess of soft tissues.

When making a gypsum negative with an excess of soft fabrics,

put a nylon cover on the stump, pulled through a hole made in the

frozen negative, in order to distribute them more evenly.

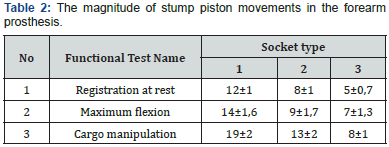

Result

The results of measuring the piston movements are shown in

Table 2.

Discussion

The data obtained indicate a significant decrease in the

appearance of the resulting piston motions. At a small number

of patients, at the same time, observed minor deviations from

the mean value. Since the study involved patients with complex

stumps, it is possible to conclude that it is necessary to show such

patients prostheses with receptacles according to option 3. That

correlates with [37-39].

On the basis of the obtained results, it can be stated that

combined full-contact, non-coincident sockets have a number

of advantages over traditional (rigid) casings. They allowed to

realize the following possibilities:

1. good fixation of prostheses with minimal piston-like

movements, which contributes to a feeling of feedback when

using workers and active prostheses with a traction control

system;

2. prosthetics of disabled people with varying stump

parameters;

3. providing an elastic inner surface of the covers and

supporting elements, which completely repeat the contours of

the stump and assume external shock loads;

4. increasing the level of cosmetic prosthetics and

improving the appearance, due to the elimination of additional

fastening elements [40].

Conclusion

The use of combined sockets allows you to level out minor

errors in prosthetics, which reduces the consumption of materials

and labor costs in the manufacture of receptacles and fitting

prostheses. And this, in the final analysis, reduces the total cost

of prosthetics. This is an advantage for developing countries.

Practical experience in the prosthetics of the disabled with upper

limb defects indicates a significant increase in the functionality

of the prosthesis when using individual combined sockets for the

prosthesis of the forearm, taking into account the anatomical and

morphological features of the truncated limb.

Standard Protocol on Approvals, Registrations, Patient Consents

All patients wrote the individual protocol.

Conflict of Interest

The use of combined sockets allows you to level out minor

errors in prosthetics, which reduces the consumption of materials

and labor costs in the manufacture of receptacles and fitting

prostheses. And this, in the final analysis, reduces the total cost

of prosthetics. This is an advantage for developing countries.

Practical experience in the prosthetics of the disabled with upper

limb defects indicates a significant increase in the functionality

of the prosthesis when using individual combined sockets for the

prosthesis of the forearm, taking into account the anatomical and

morphological features of the truncated limb.

Acknowledgement

Designed research, collected data, analyzed data-Zamilackij

YU.I.; collected data, wrote paper – Marusin N.V., Golovin M.A.

For more articles in Open Access Journal of Engineering Technology please click on: https://juniperpublishers.com/etoaj/index.php

Comments

Post a Comment