Influence of Wiper and Conventional Inserts at Profile Geometry During Turning of D2 Tool Steel - Juniper Publishers

Juniper Publishers - Open Access Journal of Engineering Technology

Abstract

Latest inventions in the field of manufacturing drive

the new technologies and different sources of production and to design

the various sources to enhance the productivity as well as to reduce the

cost, while maintaining the required specifications and high standards

of the products. For achieving the production with high quality, tool

manufacturers are continuously improving cutting edge, coating, geometry

and the material of the tool. The tool geometry affects different

aspects of tool like cutting temperature, tool wear and tool life,

surface roughness, dimensional accuracy and surface integrity in the

machining. The existing study is an attempt to explore the effect of

wiper and conventional insets at profile turning. In this research

inserts (wiper and conventional) having three different tool of nose

radius (0.4, 0.8 and 1.2mm respectively) were evaluated at cutting speed

(150m/min), feed rate levels (0.05. 0.10, 0.15, 0.20mm/rev), and depth

of cut (0.2mm). Workpiece surface roughness (Ra) dimensional accuracy

and microhardness of the machined surface were assessed. It was found

that in profile turning in case of conventional inserts with larger nose

radius of 1.2mm performed better than the other two inserts in term of

surface roughness and dimensional accuracy. While in case of wiper

inserts surface roughness and dimensional accuracy results were not

better as comparing to conventional inserts. Microhardness under the

machined surface was increased in both the cases of wiper and

conventional.

Keywords: Profile turning; D2 tool steel; Inserts (Wiper and Conventional); Dimensional Accuracy; Surface roughness; MicrohardnessIntroduction

Hard part turning which is also known as hard

turning (HT) is the machining of material having hardness more than 60

HRC, these types of materials are cut with CBN and Ceramics tools [1].

In the hard turning process, not only operating parameters and geometry

of tool are important but also the material composition and tool type

are the elements that influence the surface finish of the product.

Previous literature indicates that, in order to increase efficiency in

terms of tool life, surface roughness, tool geometry and surface

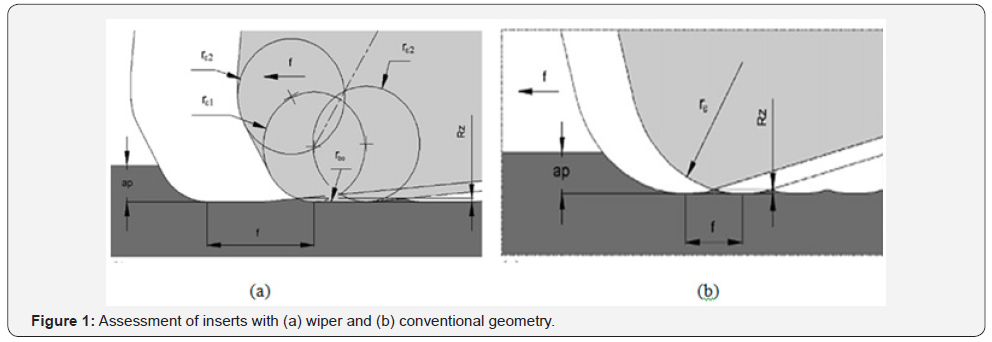

integrity are the parameters that are to be considered [2]. The wiper

technology for turning is made up of series of radii that form the

cutting edge. In wiper insert adjacent to nose radius, 3 to 9 smaller

radii were introduced [3]. To ensure a better surface finish, operating

parameters are important and selected very carefully [4], tool geometry

and material [5], and

surface reliability is very essential for the machined components having

elevated thermal and mechanical stresses [6]. Authors conducted an

experimental study while machining D2 tool steel with wiper inserts and

found that feed rate is the major factor that affects the surface

roughness. Further in depth analysis of surface integrity microhardness

was extended up to 150μm beneath the machined surface, and no white

layer formation was found after machining [7]. Denni Kurniawan et al.

used wiper inserts for the metal removal process of martensitic

stainless steel at different material removal speeds and feed rate, and

found that combination of truncated feed rate and speed generated the

higher tool life with better surface finish [8]. D.M. D’Addona &

Sunil J. Raykar carried an experimental research to find out the effect

of wiper and conventional inserts during turning of oil hardening non

shrinkage steel. From the analysis, it can be seen that wiper inserts

performance in term of surface

finish was better than conventional insert in the simple turning

process. It was also concluded that feed was the most dominant

factor than the other operating parameters that affects the

surface finish [9]. In another study, PCBN tools were employed

to machine AISI D2 steel and noticed that the most reasonable

speeds and feeds were in the assortment of 70-120m/min,

0.08-0.20mm/rev respectively. Higher tool lifespan and metal

removal rate obtained at lower speed and uppermost feed rate

shows that lower speed is more feasible for the machining at

the certain range of parameters combinations; however, highest

feed decreases the tool life [10]. An experimental research was

carried out on the mach inability characteristics of specific

cutting force, power, machining force, tool wear and surface

roughness (Ra) while machining of AISI D2 tool with inserts

(conventional and wiper ceramic). The analysis indicated that

the tool wear decreased by increasing depth of cut up to 0.4mm,

when GC6050WH and CC650 inserts were used it suddenly

increased. It was also noticed that tool wear increased gradually

with the depth of cut while using CC650WG. CC650WG type wiper

insert performance was enhanced in term of exterior roughness

and tool wear [11]. HA Kishawy and MA Elbestawi inspected the

surface integrity and tool wear while machining D2 tool steel.

Effect of different cutting factors on edge preparation, surface

and subsurface damage and tool wear was examined. From the

scanning electron microscope (SEM) analysis it was noticed that

surface integrity conditions changed significantly with various

operating conditions. In addition to that a fine surface finish was

obtained at high cutting speed from worm tool and white layers

were observed on the subsurface [12]. In another experimental

study, during the finishing operation of turning of D2 tool steel

using ceramic wiper (multi-radii) tools, the tool lifespan, flank

wear and exterior roughness were inspected. From the analysis

it was concluded that exterior roughness was in the series of

0.18-0.20μm using wiper tools and tool life was obtained 15min

at high cutting speed [13]. Kopac et al. suggested that surface

finish obtained by wiper inserts is similar in comparison to

machining with conventional tools at low feed rate. Whereas at

high feed rate, conventional tools provide higher value of surface

roughness as compared to wiper inserts [14].

Researchers carried out numerous experiments to examine

the effect of operating limitations on Ra in turning operation [15]

as it is a major parameter used in the performance of machined

components. Rzewski & Wan at, used inserts (conventional and

wiper) in rigid turning process at constant parameters, which are

depth of cut, nose radius, cutting speed, and variable feed rates.

It was concluded that both types of inserts provide similar values

of Ra at lower feed rates [16]. Cakir et al. discovered that, feed

rate had substantial influence on Ra followed by cutting speed.

A greater value of feed rate generates higher exterior roughness,

however cutting speed had an opposing result and depth of cut

had no major influence [17]. Prasad et al. investigated that Ra

values rise with escalation in speed, varying nonlinearly with

augmentation variation of feed conversely; depth of cut was not

affecting much on roughness values. Most of the researchers

concluded in their research that feed rate considerably affect the

surface roughness along with depth of cut and cutting speed [18].

Neslusan et al. found the effect of feed rate (0.10-0.65mm/rev)

while turning bearing steel 100Cr6 at unchanged cutting speed

(150m/min) and depth of cut (0.15mm) and made a comparison

with conventional inserts. Approximately 60% higher surface

compressive residual stresses and ~33% reduced white layer

thickness has been reported. The surface integrity attributes

were recorded when feed rate was low (0.225mm/rev) [19].

Amini & Paktinat [20] used mixed alumina multi radii inserts

while turning Monel K500 at feed rates ranging from 0.12mm/

rev to 0.24mm/rev. Though they report 57% and 60% reduction

in cutting force and Ra respectively as compare to conventional

insert, however, no data related to tool wear has been reported.

Recently, Ferreira et al. [21] evaluated hard turning of AISI H13

steel using multi radii and conventional inserts at four levels of

feed rate (0.05, 0.10, 0.25 and 0.40mm/rev) and at a perpetual

depth of cut (0.20mm). Roughness values (Ra) obtained for multi

radii inserts were approximately 5 times less in comparison to

their conventional counterparts.

Experimental Detail

The current study was conducted to explore the effect

of inserts (wiper and conventional) geometry on the profile

turning of D2 tool steel. Two-axes CNC lathe machine was used

for experiments. Experiments were performed at high chromium

heat treated AISI D2 tool steel with chemical configuration of

C=1.51%, Si= 0.42%, Mn= 0.37%, Cr=15%, Mo=1.3%, V=0.80%.

A bar of dimensions 70 mm diameter and 22mm length with

a hardness value of 59±1HRC was used for experimentation.

Mixed alumina TiN coated ceramic inserts having 71%Al2O3,

28%TiC&1% other were used having conventional and wiper

geometry. Rhombic shaped Wiper tool geometry having 0.4mm,

0.8mm and 1.2mm nose radius corresponding to ISO code CNGA

120404 S01525 WH (0.4mm), CNGA 120408 S01525WH (0.8mm)

and CNGA 120412 S01525WH (1.2mm) [Ref. CC6050WG]. The

conventional inserts had chamfered plus honed edge and also

TiN coating having nose radius of 0.4mm, 0.8mm and 1.2mm

with ISO code CNGA 120404 S01525 (0.4mm), CNGA 120408

S01525 (0.8mm) and CNGA 120412 S01525 (1.2mm) [Ref.

CC6050] (Figure 1).

The inserts had an 80° rhombic shape with cutting edge

length of 12mm. The insert thickness was 4.76mm. A single

insert had four cutting edges. The geometry of the inserts

provided 6° clearance angle with a negative rake of 6°, cutting

edge inclination angle of -6° and cutting edge angle of 95°.

Tool holder with ISO code of MCLNR 2020K12 was used

to mount these inserts throughout the experiments. The tool

holder gave rake angles of 5° to tool’s end and back. Similarly,

end cutting edge angle was also 5° while -5° was side cutting

edge angle. The end and back rake angles were -5° as negative

rakes are common in hard machining but the effective rake was

positive.

In the current study two factors involving feed rate at 4

levels and nose radius at 3 levels were investigated using full

factorial design. Each tool nose radius was evaluated against

different values of feed rate (0.05, 0.10, 0.15 and 0.20mm/rev)

at continuous cutting speed (150m/min) and depth of cut (0.2

mm), in order to find out the exterior roughness and dimensional

precision using complete factorial design. All inserts of (0.4,

0.8, 1.2mm) were evaluated at different feed rate value. The

experiments were performed separately for both the wiper and

conventional inserts. Experiments were performed without

using any coolant (Figure 2).

Results and Discussion

Surface roughness

Exterior roughness is the key factor that is used to measure

the performance of the machined part, less value of surface

roughness is necessary to manufacturing work piece, it reduces

the coefficient of friction and wear rate besides improves the

corrosion resistance properties [22].

In the current study, workpiece surface roughness values

were taken at corresponding feed rate with the three types of

inserts while machining at the given conditions of constant

cutting speed, depth of cut and varying feed rate. The values

were also taken at the start and end of tests so as to learn the

range of surface roughness variation for a particular test. An

evaluation length of 4mm was selected to measure Ra value

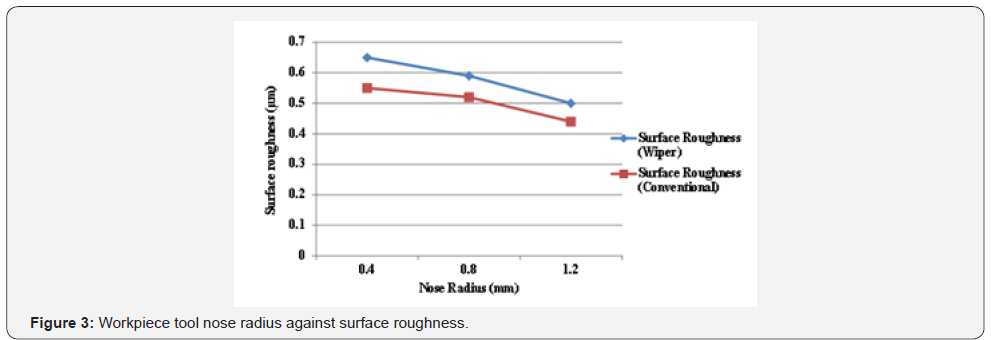

at the profile. From the analysis it was observed that surface

roughness (Ra) values decreased while increasing the nose

radius of the tool, but instead specific cutting energy to some

extent increased with increasing the nose radius because of large

contact area of the tool. The minimum value of surface roughness

0.44μm was achieved with the conventional tool at large nose

radius of 1.2mm. So conventional tools provided better results

in comparison to the wiper tools in the profile turning. Following

Figure 3 represent the workpiece surface roughness with respect

to each tool nose radius.

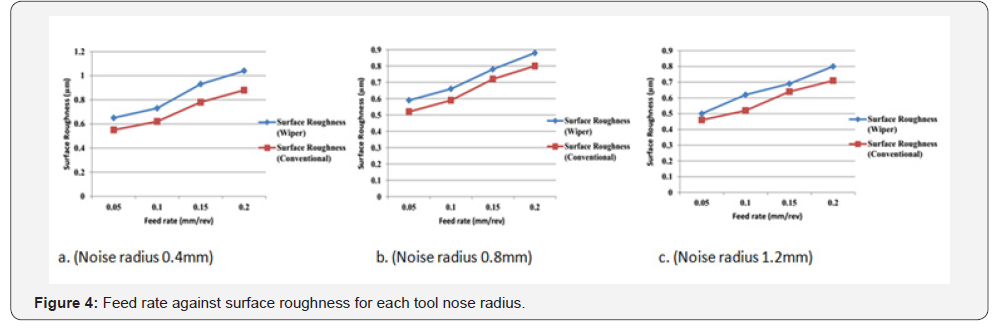

Similarly, each nose radius was evaluated to investigate the

feed rate against surface roughness. From the graphs it was

perceived that, surface roughness increased while increasing the

feed rate due to large uncut chip thickness. While in comparing

both the tools, conventional tools provided better results in term

of surface roughness than wiper tools in each tool nose radius.

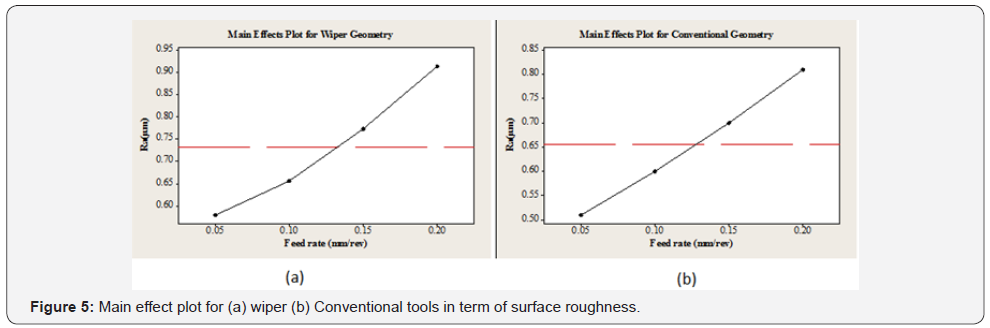

Following graphs represent the workpiece surface roughness with respect to feed rate for each tool nose radius. A similar kind

of trend was observed in the foremost influence plot for surface

roughness. The graph also indicated that workpiece surface

roughness increased with the rise in feed rate. Maximum surface

roughness was observed at maximum feed rate, while lower

value of surface roughness was noticed at smaller value of feed

rate for both the wiper and conventional tools. The main effect

plot in Figure 4, 5 showed that, in the process of profile turning,

better results were achieved by conventional tools as compared

to the wiper tools.

Dimensional accuracy

The dimensional accuracy is the important key to ensure the

achievement of correct functioning of parts machining. Nowadays

many manufacturers try to produce good machining parts or

components with good dimensional tolerance in order to fulfil

customer requirements. Normally, dimensional accuracy of the

machining parts depends on the machining process that involves

in the selection of cutting parameters. In the current research

dimensional accuracy of the machined surface against feed rate

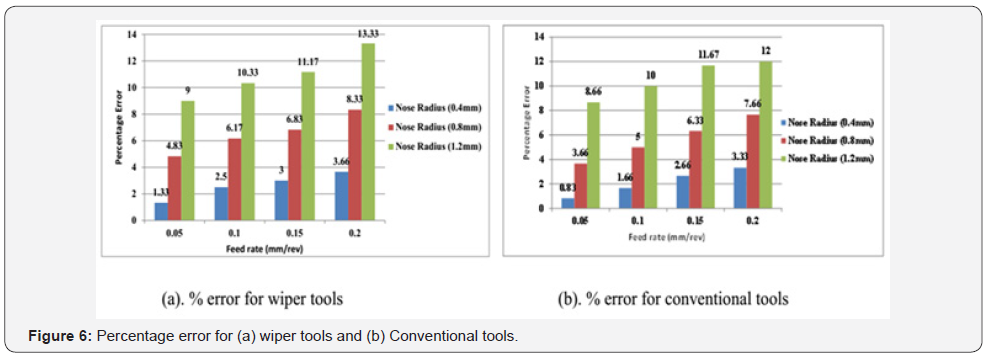

for each tool nose radius was investigated. The analysis reveals that, with the dimensional accuracy increased by increasing

the feed rate for both the cases. It was also observed from the

graphs that percentage error for the conventional tools was less

than the wiper tools. The conventional inserts provided better

dimensional tolerance in comparison to the wiper inserts in the

profile turning process, the main effect plot in Figure 6 showed

that surface finish decreased by increasing feed. In the process

of profile turning, better results were achieved by conventional

tools as compared to the wiper tools. The main effect plot in

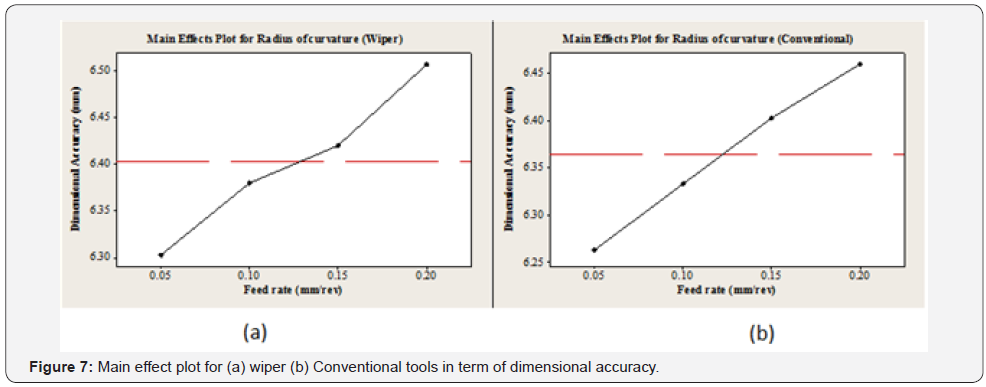

the Figure 7 indicated that higher value of radius of curvature

was achieved by wiper tools in comparison to the conventional

tools, So a significant deviation was notice in term of radius of

curvature in the wiper tools.

Micro hardness

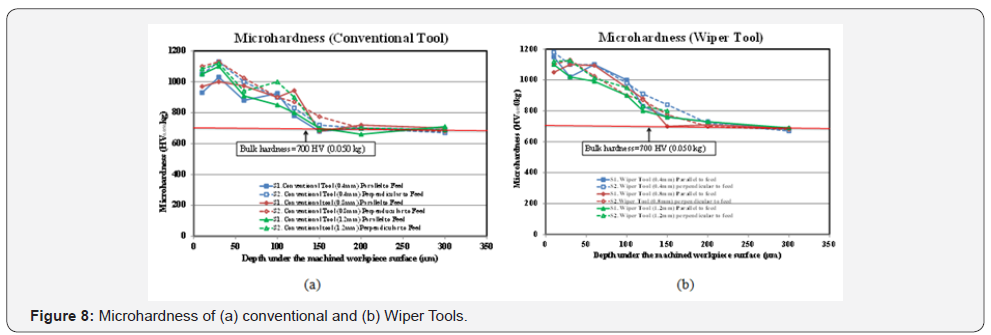

Microhardness under the machined surface was measured

at a distance of (10, 30, 60, 100,120, 150,200 and 300μm).

Indenter was placed at the workpiece surface at different

location in the zigzag form to measure the diagonals of the

indenter. Microhardness was measured for the samples that

were machined for both the new and worn tools. Following

observations were noticed from the graphs. It was observed

from the graph that microhardness was increased under the

machined surface, and uniformly decreases as the depth under

the machined surface increased. It was also observed from the

graph that microhardness under the machined surface for both

new and worn tools at the distance of 10μm was increased

1.4 to 1.6 times more than the bulk hardness of the material.

In comparison to the new and worn tools similar results were

obtained that microhardness was increased near the machined

surface. Although larger values of microhardness were observed

under the machined surface at 10μm for worn tools because

of mechanical stresses and vibration tendencies increased. It

was also noticed that micro hardness become stable under the

machine surface after 150μm (Figure 8).

Acknowledgment

The authors appreciatively acknowledge the management

and laboratory staff of Pakistan Industrial and Technical

Assessment Center (PITAC) Lahore, for their cooperation and

permission for using machines and other measuring equipment.

Authors also thanks to the lab staff of Department of Material

and Metallurgical Engineering University of Engineering and

Technology Lahore, Pakistan.

Conclusion

The statistical analysis revealed that tool geometry and

cutting parameters have noteworthy influence on the work piece

surface finish. It was found that, in profile turning process while

using conventional inserts with larger nose radius of 1.2mm

produced better surface finish than the other two nose radii i.e

0.8mm and 0.4mm. The surface roughness at 1.2mm nose radius

is 15% less than that at 0.8mm and 20% less than that at 0.4mm

nose radius. Almost same trend appeared while using wiper

inserts of respective nose radii. As comparison between wiper

and conventional inserts, at 1.2mm nose radius, conventional

inserts resulted 20% lower surface roughness than as with

wiper inserts and it remained lower at other nose radii also. It

was also established that increase in the feed rate value resulted

the decrease in surface finish but surface finish for conventional

inserts was 5% better than that with wiper inserts. While in

case of dimensional accuracy, conventional inserts with larger

nose radius performed better than wiper tools. At lowest nose

radius, dimensional accuracy in term of profile turning from

wiper inserts was almost 32% less than that with conventional

inserts and at higher nose radius this difference of dimensional

accuracy reduced to 4% between wiper and conventional inserts.

Microhardness shows a mix behavior for wiper and conventional

inserts and same trend is appeared for both inserts.

For more articles in Open Access Journal of

Engineering Technology please click on:

Comments

Post a Comment