Juniper Publishers Minimum Equipment List as a Mechanism of Motion in MIRCE Mechanics

Juniper Publishers - Open Access Journal of Engineering Technology

Authored by : Knezevic J

Abstract

To avoid the loss of consumer trust, revenue or

capability any disruption to a system's functionality is unacceptable to

the providers, on one hand and also to their receivers, on the other.

Consequently, every effort must be made to ensure the continuity of the

provision of the system's functionality through calendar time. One of

the methods used to minimise disruption to operational capability,

especially in the aviation industry, was the creation of the Minimum

Equipment List (MEL). This list identifies the equipment/components

present into system that are not necessary to be operational for the

safe provision of the functionality of the system, in accordance with

the prescribed operational and maintenance restrictions, and approved by

the regulatory authorities. Consequently, the main objective of this

paper is to present the concept of the MEL as one of the potential

mechanisms to be used outside aviation community to further influences

the motion of a functionable system type through MIRCE Space and

potentially enhance its functionability performance as perceived by

MIRCE Science.

Keywords: Electron; Positive functionability action; Positive functionability state; Negative functionability state; Mechanism

Abbreviations:

PFS: Positive Functionability Action; NFS: Negative Functionability

State; PFA: Positive Functionability Action; NFA: Negative

Functionability Action; PFE: Positive Functionability Event; NFE:

Negative Functionability Event

Introduction

"Motion does not mean travel of the ball-type

electron along some orbit around the nucleus. Motion is the change in

the state of the system “atom” in time.” Werner

Heisenberg

To facilitate the flow of functionality through

calendar time provided by the functionable system types MIRCE Science is

focused on the scientific understanding and description of the physical

phenomena and human rules that govern their in-service behaviour.

According to Knezevic [1],

functionable system type is “a set of mutually related components

uniquely put together to perform at least one measurable function and a

set of functionability rules that govern its Functionability

performance.”

In MIRCE Science, at any instant of calendar time a given functionable system type could be in one of the following two states:

1. Positive Functionability State (PFS), a generic

name for a state in which a functionable system type is able to deliver

the expected measurable function(s),

2. Negative Functionability State (NFS), a generic

name for a state in which a functionable system type is unable to

deliver the expected measurable function(s), resulting from any reason

whatsoever

The motion of a functionable system type through the

Functionability states, in the direction of calendar time, is generated

by Functionability actions, which are classified as:

1. Positive Functionability Action (PFA), a generic

name for any natural process or human activity that compels a system to

move to a PFS.

2. Negative Functionability Action (NFA), a generic

name for any natural process or human activity that compels a system to

move to a NFS.

The motion of a functionable system type through the

functionability states is manifested through the occurrences of

Functionability events, which are classified as:

1. Positive Functionability Event (PFE), a generic

name for any physically observable occurrence in time that signifies the

transition of a functionable system type from a NFS to a PFS.

2. Negative Functionability Event (NFE), a generic

name for any physically observable occurrence in time that signifies the

transition of a functionable system type from a PFS to a NFS.

Transition of a functionable system type from PFS to

NFS and loss of functionality is undesirable in private sector due to

loss of revenue and to public sector due to loss of benefits. For

example, in airline business loss of service is unacceptable due to

negative consequences of the following types: [2].

1. Loss of income generated by transporting passengers and cargo

2. Poor customer relationships

3. Increased demand for support resources (spares, tools, equipment, etc).

4. Increased numbers of maintenance facilities,

including skills and training of personnel required to deal with the

consequences of cancellations.

5. Costs arising from re-routes, aircraft substitution, passenger handling (hotels, buses, meal vouchers).

Cancelled flights generate the cost to the customer

too, due to disrupted plans, missed business appointments, lost time and

poetical consequences to the cargo due to late shipments.

Generally speaking, all affords must be made to

enable passengers and cargo to go to their destinations on time, in safe

manner Legendary Chief Mechanic on Boeing 777, Jack Hessburg, has

immortalised this sentiment by saying, "All I want to do is to go to

Cleveland on time and never crash” [1].

Consequently, the main objective of this paper is to

present the concept of the MEL as one of the potential mechanisms to be

used outside aviation community to further influences the motion of a

functionable system type through MIRCE Space and potentially enhance its

functionability performance as perceived by MIRCE Science [1].

Minimum Equipment List in Commercial Aviation

According to Hessburg [2],

the structure and approval of the early Minimum Equipment Lists (MEL)

lists were principally in the hands of the individual CAA Air Carrier

Inspectors. Technical evaluation of items for inclusion into a list was

based upon the individual inspector's knowledge, competence, and

subjective analysis of a specific aircraft type. The result was that the

MEL for operator “A” and that operator “B” (both using the same model

aircraft) were frequently different; one airline's inspector being very

conservative and disallowing all but the simplest of equipment to be

inoperative, the other being far more liberal. Individual operators

would claim favouritism when one discovered that their competitor had a

less restrictive MEL.

This lack of objective analysis and standardisation

of MEL resulted in the institutionalisation of the process by the mid-

1960s. The FAA adopted centralised control and publication of separate

Master Minimum Equipment Lists (MMEL) for each large aircraft type.

Present regulations continue to recognise the

original MEL concept. FARs 125, and 135 operators were included in the

concept by the late 1970s. In 1991, single engine operations under FAR

135 were added to the concept. Lastly, FAR Part 91 operations are also

now covered [3].

It is necessary to stress that nothing in this

concept disallows the authority of the pilot-in-command. The pilot may,

at his or her discretion, require that any item covered by the MEL be

repaired before flight.

Operations with certain items of equipment

inoperative are not considered an abrogation of the aircraft Type

Certificate. When operating under Parts 121, 125 or 135, an approved

Minimum Equipment List is recognised as an approved change to the type

design. Therefore, the altered status of the aircraft under the MEL

remains an acceptable certified configuration. Consequently, adoption of

an MEL item does not require recertification of the type design [3].

Operating with an approved MEL and a letter of

authorisation under FAR Part 91 constitutes a Supplemental Type

Certificate for the aircraft. As such, an MEL approved under Part 91 is

issued against a specific aircraft(s) i.e. aircraft serials number(s).

The aircraft(s) will be listed on the cover sheet of the approved MEL.

Is necessary to stress a mechanic or inspector is not

in violation of the FAR for releasing an aircraft as airworthy when

certain items are inoperative under an approved MEL. Because an air

carrier airworthiness release requires certification that the work

performed is in accordance with the certificate holder's manual. Because

an approved MEL is a part of the certificate holder's manual, a

mechanic is relieved of responsibility for the inoperative status of MEL

items. The actions taken under the requirements of an approved MEL

would “clear” the discrepancy from the aircraft maintenance record and

would consequently revalidate the maintenance release.

A mechanic is not responsible for any contingent

maintenance required by the MEL for any previously deferred items unless

additional or repetitive maintenance is required. An aircraft

maintained under FAR Part 91 is returned to service under the provisions

of FAR 43.5 and is unaffected by this dilemma as an approved MEL under

Part 91 is considered a supplemental type certificate.

Creation of the Master Minimum Equipment List

During the initial design of an aircraft the

development of Master Minimum Equipment List, MMEL, begins. For new

designs, the manufacturer submits a preliminary list of items to be

considered by the relevant aviation authorities. Aircraft operators,

interested public (safety organisations, foreign regulatory agencies,

union representatives, and the like), use this list to develop the

master. The final MMEL is released, after approval by designated

authority.

Once adopted, an MMEL is periodically revised. These

revisions arise from individual operators petitioning the relevant

authorities for additions, deletions, or clarification of items. These

changes continue throughout the useful life of the aircraft type. There

is no set schedule for the revisions; they take place on an as needed

basis. Early in an aircraft model's life, meetings might be held yearly,

whereas later in its life, the meetings can be several years apart.

MMEL is for Aircraft not Airline

The MMEL is a generic list for a given aircraft type.

Thus, items are included in the master that may not be installed in a

given airline's fleet. There is no system for tracking recording, crew

notification and clearing of a deferred item contained in the list. The

list also contains time limits on how long a given item may be deferred.

It identifies requirements for placarding the cockpit. It requires

which items must have maintenance and flight operations procedures or

limits.

Each airline must prepare its own MEL using the

master as the source. Operators are responsible for exercising the

necessary control to insure that an acceptable level of safety is

maintained. This includes a repair program embracing the parts,

personnel, facilities, procedures, and schedules to insure timely

clearance of deferred items.

An individual airline's MEL may be more restrictive

but not less than the Master Minimum Equipment List. They may include,

with appropriate conditions and limitations, items not contained in the

master list such as equipment not required for a given flight operation;

that which is more than required by the FAR; and equipment that, for

internal administrative control reasons to the operator, is best placed

within the context of his MEL

Deferring Process under MEL

The specific process for deferring at any given

airline will differ. However, once it has been determined that an item

is deferrable, a decision is made to defer or fix. This normally

involves, at the minimum, station maintenance personnel and the

pilot-in-command. However, in many instances, flight dispatch,

maintenance engineering and a quality control organisation will be party

to the decision. Some airlines designate in the body of their MEL,

specific individuals or organisations with deferral authority for each

item listed.

Station maintenance personnel have several

responsibilities that include properly securing the deferred item,

logging item correctly in required documents, notifying specific

individuals and organisations to ensure that the necessary bookkeeping

will take place, thus insuring that the item is properly tracked and

scheduled for later repair within allowable time limits.

Dispatch and/or the pilot-in command shall, as

appropriate observe any special limitations or modified operating

procedures attendant to the deferred item and notify other operations

organisations and down line stations that are affected by the deferral.

Maintenance control or other appropriate organisation

charged with tracking deferred items and scheduling will take

appropriate action to clear the item from the deferred log within the

allowed time for deferral.

An Example of Minimum Equipment List

To illustrate the concept and a practical application

of MEL the vacuum pump of Piper SeminolePA-44-180 is addressed, for no

particular reason. It is a four seat light twin aircraft, which has been

in-service since 1978. It is at twin engine development of PA-28 Archer

aircraft with new T-tail and semi-tapered wings. Production ceased in

1981, restarted in 1988 and ceased once more in 1990.

Main technical and functionality characteristics of this aircraft are as following:

1. Power plants: Two 135kW (180hp) Lycoming 0-360-

E1AD flat four piston engines driving two or optionally three blade

constant speed Hartzell propellers.

2. Performance: Max speed 311km/h (168kt), max

cruising speed 309km/h (167kt), long range cruising speed 280km/h

(151kt). Initial rate of climb 1200ft/min. Service ceiling 17,100ft.

Range with reserves 1630km (880nm). Weights: Empty 1070kg (2360lb), max

takeoff 1723kg (3800lb).

3. Dimensions: Wing span 11.77m (38ft 8in), length 8.41m (27ft 7in), height 2.59m (8ft 6in). Wing area 17.1m2 (183.8sq ft).

4. Production: Total Seminole production through to end 2004 amounted to 672, including 86 Turbo Seminoles.

The Piper PA-44 Master Minimum Equipment List (MMEL)

for Part 91 operations lists all items of installed equipment that are

permitted to be inoperative. The MMEL states, in part, that “it is

incumbent on the operator to endeavour to determine if Operations and/or

Maintenance] procedures for that equipment must be developed.

The MMEL is intended to permit operations with

inoperative items of equipment for the minimum period of time necessary

until repairs can be accomplished. It is important that repairs be

accomplished at the earliest opportunity in order to return the aircraft

to its design level of safety and reliability. Operators are

responsible for exercising the necessary operational control to ensure

that an acceptable level of safety is maintained” [4].

According to Section 37 “Vacuum/Pressure,” sequence

title "1. Vacuum Pump” states “two vacuum pumps are installed and one is

required for dispatch. It further provided, under the “Remarks or

Exceptions,” that “One may be inoperative for day VFR flights”.

The PA-44 Scheduled Maintenance Manual includes a

checklist to be utilised for inspections every 50 and/or 100 hr.

Subsection B.36 states “Inspect and operationally test vacuum pumps and

lines.” It further requires that the vacuum pump installed on each

engine is inspected every 100 hr. Note 7 further states "Replace or

overhaul, as required, or at engine overhaul”

The Pilot's Operating Handbook states in Section

7.19. “The vacuum system operates the air-driven gyro instruments. The

vacuum system consists of a vacuum pump on each engine, plus plumbing

and regulating equipment. A shear drive protects the engine from damage.

If the drive shears, the gyros will become inoperative. The vacuum

gauge mounted on the right instrument panel to the right of the radios

provides valuable information to the pilot about the operation of the

vacuum system (A low vacuum indicator light is provided in the

annunciator panel). In the event of any gauge variation from the norm,

the pilot should have a mechanic check the system to prevent possible

damage to the system components or eventual failure of the system. A

vacuum regulator is provided in the system to protect the gyros. The

valve is set so the normal vacuum reads 4.8 to 5.2 in. of mercury” [4].

Should suction drop below 4.5 in. Hg, pilots are

cautioned to increase rpm to 2,700, descend to maintain 4.5 in. and use

the electric turn indicator to monitor directional indicator and

attitude indicator performance.

Impact of Minimum Equipment List on Functionability Performance

"We did not buy the airplane to make a roost for

pigeons on the vertical fin, fouling the logo. So equipment availability

is a fundamental tenant which we forget about”

Bob Six, CEO Continental Airlines According to the

philosophy of MIRCE Science the main objective of existence of any

functional system is to do a work during the calendar time. [1]

To differentiate the concept of work in physics and in MIRCE Science,

the author has named the latter as a functionability work. Hence,

functionability work is considered done when a system delivers a

measurable function over an interval of time, in a similar way that

classical physics considers work done when an external force displaces

an object over a distance.

Consequently, in MIRCE Science functionability work is classified as [1]:

1. Positive Functionability Work (PFW): a generic

name for the physically measurable performance of a functionable system

type proportional to the duration of the calendar time during which the

expected function(s) are performed, measured in hours [Hr].

2. Negative Functionability Work (NFW): a generic

name for the physically measurable performance of a functionable system

type proportional to the duration of the calendar time during which

required positive functionability actions are performed, measured in

hours [Hr].

Although the concept of functionability work is the

main measure of functionability performance, it is necessary to take

into account the physical resources related to the execution of

functionability works, like material, personnel, spares, tools,

equipment, facilities and energy and similar must be taken into account.

As all of them have individual monetary values, in MIRCE Science, they

are brought together under the single umbrella of functionability cost,

and it is classified into following two types [1]:

1. Cost of Positive Work (CPW): a generic name for

the physically measurable performance of a functionable system type

determined by the monetary value of all the resources related to the

delivery of positive functionability work, like operational personnel,

consumable material, equipment, facilities, energy and similar.

Generally speaking, it encompasses all the costs related to delivery of

the positive functionability work by the functionable system type during

a given interval of calendar time T, denoted as CPW (T). It is equal to

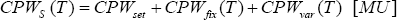

the sum of the following cost elements: [1]:

Where: CPWset is the Set up Cost, CPWfix (T) is the Fixed Cost and): a CPWvar is the Variable Cost of delivering positive work.

2. Cost of Negative Work (CNW): a generic name for

the physically measurable performance of a functionable system type

determined by the monetary value of all the resources used by a

functionable system type to perform the negative functionability work,

like spare parts, qualified personnel, material, equipment, facilities,

energy and similar. Thus, it encompassed all the costs related to

performing the negative functionability work, performed on the

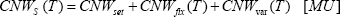

functionable system type during a given interval of calendar time T,

denoted as CNW (T), is equal to the following sum [1].

Where: CPWset is the Set up Cost, CPWfix (T) is the Fixed Cost and): a CPWvar is the Variable Cost of delivering positive work.

The delivery of positive and negative function

ability work through time uniquely determines the positive and negative

function ability costs that correspond to the motion of a function able

system type through the function ability states. As this motion is in

the direction of calendar time, it means that the magnitudes of the

positive and negative function ability costs are non-decreasing

measurable characteristics of the function able system types, and as

such they are "legitimate” measures of their overall function ability

performance [1].

Cost of Lost Revenue

The main business of any business is staying in

business. For that to happen it is essential to generate a profit, which

is commonly accepted as the difference between the revenue generated

and the costs incurred to generate the revenue. Generally speaking, the

revenue generated by each functionable system type during a given

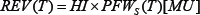

interval of calendar time, denoted as REV (T), could be calculated as

the product of the hourly

income, denoted as HI, expressed in [MU/Hr] and the amount of the

positive functionability work done by the system during the stated

interval of calendar time, PFW (T) expressed in [Hr], thus [1]:

Financially minded analysts totally ignore the

non-generated cost while the functionable system type is in the NFS

during a given interval of calendar time. However, MIRCE Science this

cost category has been analysed and named the Cost of Lost Revenue, CLR

(T) [1].

This cost category could be even higher than that of revenue generated

due to the potential consequences of the occurrences of NFEs to the

business and environment.

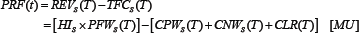

In MIRCE Science a profit, PRF (T), is equal to the

difference between the revenue, REV (T) and the Total Function ability

Cost, during the stated period of calendar time, TFC(T), thus [1]:

The MIRCE Profitability Equation is the only one,

known to the author, which unifies all aspects of the function ability

performance of a functionable system type including the cost of lost

revenue, which, in reality, is an in-separable element of the expected

profit. This equation enables more accurate predictions of the expected

profit to be made for each operational scenario, maintenance policy and

support strategy, including the “length of MEL”. Also, this equation

“integrates” the decision makers of functional systems types and the

decision makers of corresponding functionable system types into a single

“normalised” analytical entity, rather than, as currently considered,

two competing parties searching self set targets in isolation.

Conclusion

To avoid the loss of consumer trust, revenue or

capability any disruption to a system's functionality is unacceptable to

the providers, on one hand and also to their receivers, on the other.

Consequently, every effort must be made to ensure the

This work is licensed under Creative Commons Attribution 4.0 License

continuity of the provision of the system's functionality through

calendar time. One of the methods used to minimise disruption to

operational capability, especially in the aviation industry, was the

creation of the Minimum Equipment List (MEL).

A minimum equipment list (MEL) is a list which

provides for the operation of aircraft, subject to specified conditions,

with particular equipment inoperative (which is) prepared by an

operator in conformity with, or more restrictive than, the Master

Minimum Equipment List, established for the aircraft type. (ICAO Annex

6: Operation of Aircraft)

The MMEL is a list established for a particular

function able system type by the organization responsible for the type

design with the approval of the State of Design which identifies items

which individually may be unserviceable at the commencement of a flight.

The MMEL may be associated with special operating conditions and rules.

The impact of introducing the MEL for any aircraft

type could be quantified through the functionability performance

measures, namely function ability work and function ability cost,

positive and negative, which are fully defined by the function ability

equations of MIRCE Science.

In summary, this paper has shown that the MEL as one

of the potential mechanisms to influence the motion of a function able

system type through MIRCE Space and as such it can enhance its

functionability performance as understood through the application of

MIRCE Science [1].

For more articles

in Open Access

Journal of Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

To read more...Fulltext please

click on:

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555560.php

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555560.php

Comments

Post a Comment