Juniper Publishers High Gain Observer for Sensorless Input-Output Linearizing Control for Induction Motor with Broken Rotor Bar Fault.

Juniper Publishers Engineering Technology Open Access Journals

High Gain Observer for Sensorless Input-Output Linearizing Control for Induction Motor with Broken Rotor Bar Fault.

Authored by A Menacer

Abstract

The aim of this paper is the broken rotor bar

diagnosis for the sensorless nonlinear control (NLC) of the induction

motor (IM). The strategy of control is based on the input output

linearization control, using nonlinear high gain observer (HGO), in

order to preserve the speed regulation and compensate the fault effect

and to ensure the service continuity of the machine. The effect of the

broken rotor bar is evaluated through the analysis of the direct current

components Ids. This information can be used as an indication for the

fault diagnosis.

Keywords: Induction motor; Diagnosis; Broken rotor bars fault; Nonlinear control; Input output linearization control; High gain observerAbbreviations: IM: Induction Motor; FOC: Field Oriented Control; HGO: High Gain Observer

Introduction

The induction motor (IM) is known for its robustness,

simplicity of operation and low costs and maintenance free. Like any

motor exposed to mechanical or electrodynamics forces, it is lead to

failures [1],

it’s also may be caused by manufacturing fault, designing fault of the

engineer, environment and poor technical knowledge of the job about in

handling the motor [2].

On the other hand, vector control provides a good

performance during transient and permanent phases. However, it requires

knowledge of mechanical speed and rotor flux [3].

The difficulties of using field oriented control (FOC) arise from the

modelling uncertainties due to parameter variation, magnetic saturation,

load disturbances. To ensure a good dynamic performance, various robust

control strategies for induction motor drives have been cited in the

literature [4,5].

However, the input-output linearization control has focused attention

owing to simple design, the perfect decoupling between the rotor speed

and the flux, fast dynamic response, easy implementation and robustness

to parameter variations, and also for load disturbances [6,7].

Fault detection in electrical machines has been the subject of researches for many years [8].

Vibration is used for the detection of mechanical problems, broken

rotor bars and stator short circuits in induction motor. Vibration

analysis techniques are usually installed on costly and sensitive

machines, where the cost of such systems can be justified [9].

That is why some researchers are looking to analyze other quantities in order to solve this problem. In [10,11]

d (direct) current axis components have been looked in closed-loop. The

rotor speed and a rotor flux are estimated by high gain observer (HGO) [12,13].

The controller is based on the theory of feedback linearization. Where,

the reduced model of IM in healthy and faulty states is used.

This paper is organized as follows. In section 2, the

dynamic of the reduced model of IM is described. The input-output

linearization control is designed for the speed and flux magnitude

controls of an IM are showed in section 3. The HGO required for the

rotor flux and rotor speed estimation are presented in section 4.

Section 5, provides numerical simulation results of the proposed control

technique in healthy and faulty states of the IM, followed by the

conclusion.

Induction Motors Model with Broken Rotor Fault

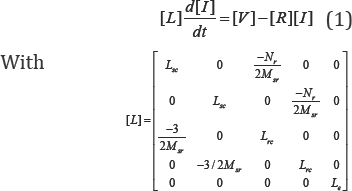

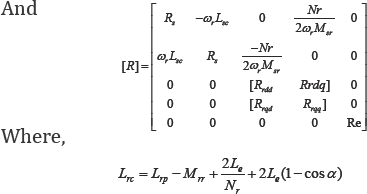

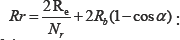

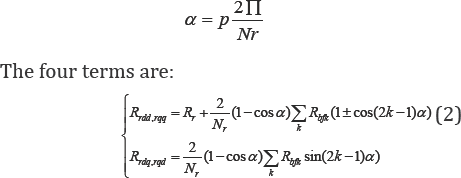

The dynamic equations of IM can be expressed as follows [14]:

Electrical angle of two rotor adjacent mesh�s.

Electrical angle of two rotor adjacent mesh�s.

In Eq. 2, the summation is applied to all bars with fault. Rbfk is the increased resistance of the bar index k from its initial value before the fault.

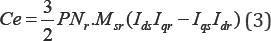

The electromagnetic torque developed by the motor is expressed in terms of rotor currents and stator currents as:

The model considered allows studying the behaviour at the healthy and faulty states of the IM in different operation cases.

Design of a Nonlinear Input-Output Feedback Linearizing Controller for Induction Motor

The input-output control problem is to find a state

feedback such that the transformed system is input-output decoupled that

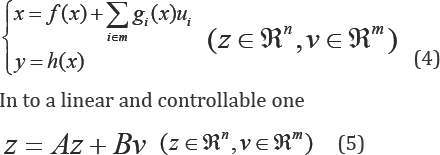

is, one input influence one output only [15]. The technique requires measurements of the state vector x in order to transform a multi-input nonlinear control system:

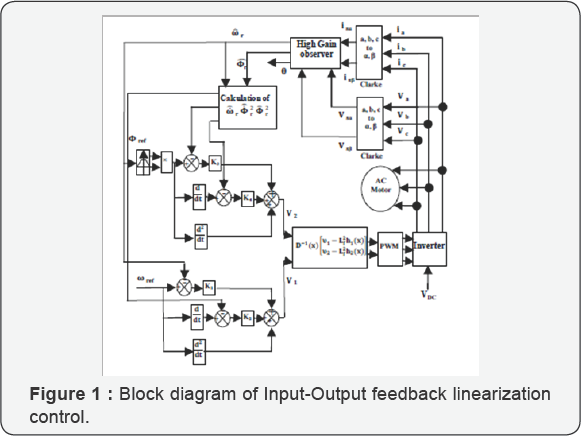

The control system is depicted in (Figure 1) [16]. The state space model of induction motor in the (a,P) frame coordinate is giVen by:

Where the state and commands vectors:

The decoupling matrix D(x) is singular if and only if Φ2r

zero which only occurs at the start up of the motor. That is, to fulfil

this condition one can use in a practical setting, an open loop

controller at the start up of the motor, and then switch to the

nonlinear controller as soon as the flux goes up to zero. If the

decoupling matrix is not singular, the nonlinear state feedback control

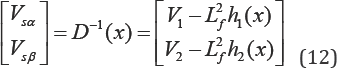

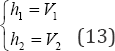

is given by:

This controller linearizes and decouples the system, resulting in:

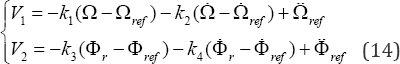

The closed loop system (13) is input-output decoupled and linear. To ensure perfect tracking of speed and flux references, V1 and V2 are chosen as follows:

Nonlinear High Gain Observer Design for Induction Motor

The dynamic behaviour in general of the induction

motor belongs to a class of relatively fast systems. For computational

issue, the high gain observer which admits an explicit correction gain

can be considered as one of the most viable candidate in the problem of

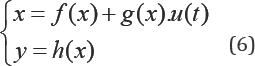

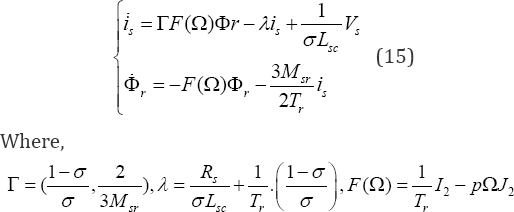

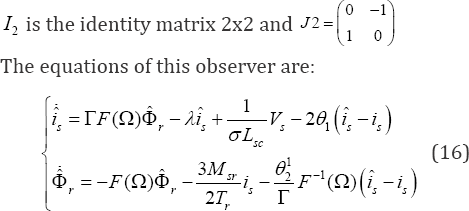

state estimation [12,17]. To study the observation and control of the induction motor, we adopt this method in our model (6), given by:

Where  and

and  are respectively the estimates of Is and Φr , Which β1, is a positive real. Therefore, the adaptive Scheme for speed estimation is given by:

are respectively the estimates of Is and Φr , Which β1, is a positive real. Therefore, the adaptive Scheme for speed estimation is given by:

and

and  are respectively the estimates of Is and Φr , Which β1, is a positive real. Therefore, the adaptive Scheme for speed estimation is given by:

are respectively the estimates of Is and Φr , Which β1, is a positive real. Therefore, the adaptive Scheme for speed estimation is given by:

Where,  , k and kt are respectively the proportional and integral constants.

, k and kt are respectively the proportional and integral constants.

, k and kt are respectively the proportional and integral constants.

, k and kt are respectively the proportional and integral constants.Simulation Results

The sensorless input-output linearization control of

induction motor used in healthy and faulty states: 1.1kW, 220V, 50Hz,

2-pole, a rotor with 16 bars were carried out using the Matlab/Simulink

simulation package. The system parameters of the induction motor tested

in this study are given in Appendix.

Healthy machine

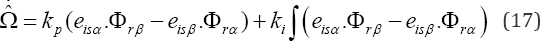

To illustrate the performances of controller in

healthy state of the machine, a simulation with reference speed equal to

1000rpm is realized in Figure 2, a nominal load torque equal to 3.5 Nm is applied at t=0.5s.

The electromagnetic torque follows the load torque and stator phase current have a very good dynamic. Quadratic rotor flux Φqr is maintained to almost zero, direct rotor flux Φdr tracks the reference values adequately well.

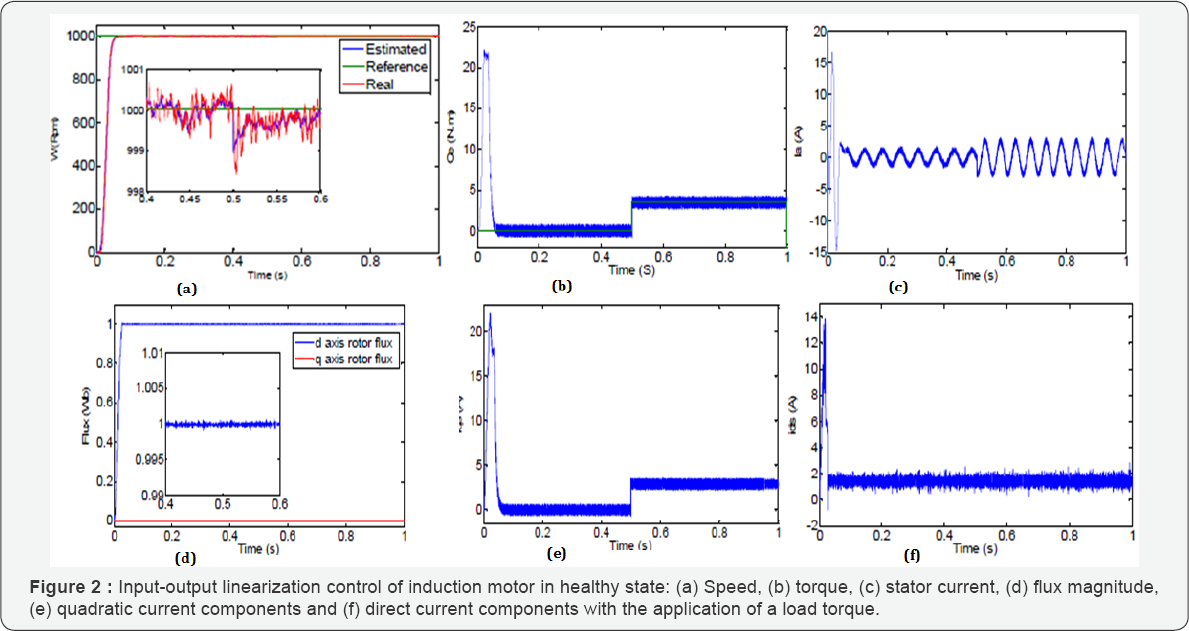

The speed reverse test is realized by changing the

speed reference from 30 rpm to -30 rpm at t=1s with a nominal load

torque 3.5 Nm is applied at t=0.5s in Figure 3.

The good performance such as robustness and

convergence of the sensorless input-output linearization control when

the induction motor operates in low reference speed. It shows that

estimate rotor speed observer and the real rotor speed converge to the

reference speed with very less errors.

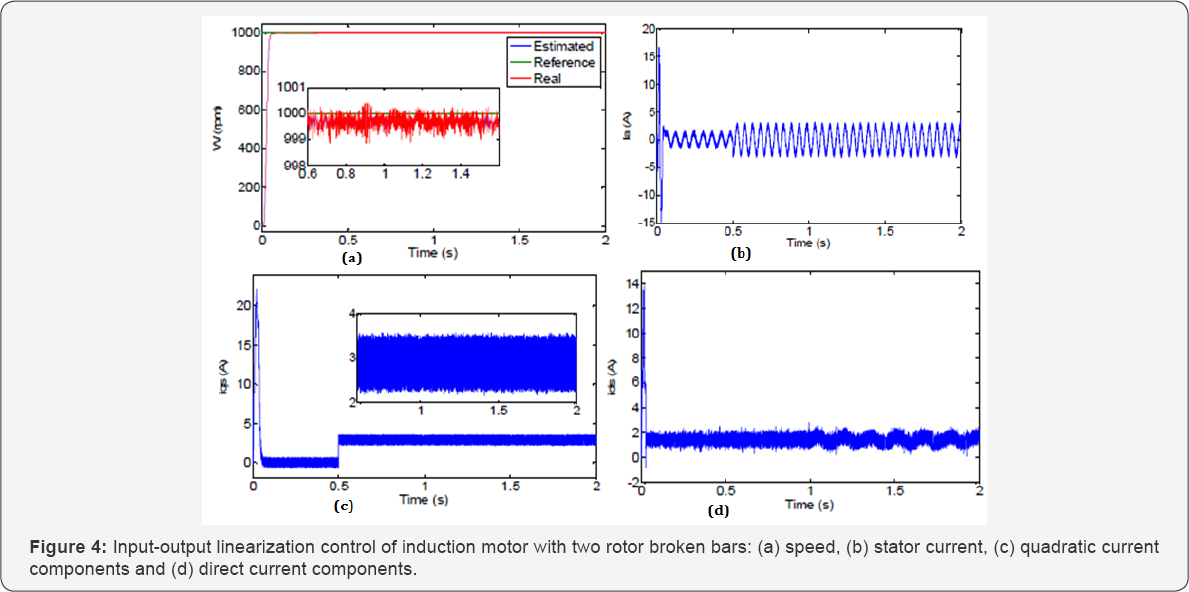

Machine with adjacent two broken rotor bars fault

In this case the sensorless input-output

linearization control of the induction motor with fault is considered.

Two adjacent broken rotor bars fault are applied at t=1s and the machine

operate at 1000 rpm with a nominal load torque 3.5Nm applied at t=0.5s.

The simulation results of sensorless input-output

linearization control using high gain observer of the induction motor

with adjacent two broken rotor bars fault are shown in Figure 4.

The rotor speed and torque give no information about the fault effect,

due to the closed loop of input-output linearization control which mask

and compensate the effect of the fault. However, the direct current Ids

is affected by the fault through the fluctuations. This information can

be exploited for the online diagnosis of the machine in closed loop.

Conclusion

In this paper, a sensorless input-output Linearizing

control for the induction motor is considered with broken rotor bars

fault. The controller shows a good performance of the induction machine

control in healthy and faulty states.

Therefore reveals a powerful sensorless input-output

Linearizing control using high gain observer for estimate the rotor

speed and Flux, Where The effect of loop control by using the speed

regulator ensures the rejection of ripples, therefore the correlation

with the fault severity is lost. The fault effect didn't affect the

rotor speed; unlike the direct current components Ids which offer a good indication for the fault effect in closed loop.

Appendix

For the simulated induction motor

pn : Output power 1.1kW

Vs : Stator voltage 220V

fs : Stator frequency 50Hz

p: Pole number 1

Rs : Stator resistance 7.58W

Rr : Rotor resistance 6.3W

Rb : Rotor bar resistance 0.15mW

Re : Resistance of end ring segment 0.15mW

Lb : Rotor bar inductance 0.1μH

Le : Inductance of end ring 0.1μH

Lsf : Leakage inductance of stator 26.5mH

Msr : Mutual inductance 46.42mH

Ns : Number of turns per stator phase 160

Nr : Number of rotor bars 16

L: Length of the rotor 65mm

g0 : Air-gap mean diameter 2.mm

J: Inertia moment 0.0054kgm2

F: Coefficient of damping 0.0029Nm/rad/s

Ce , Cr : electromagnetic torque, load torque

For more articles in Open Access Journal of Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

To read more…Fulltext please click on:

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555554.php

For more articles in Open Access Journal of Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

To read more…Fulltext please click on:

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555554.php

Comments

Post a Comment