Juniper Publishers Brief Industrial Networks Data Transfer Protocols Characteristics Analysis

Juniper Publishers - Open Access Journal of Engineering Technology

Authored by : Vladlen Shapo

Keywords

Keywords: Industrial networks; Protocols; Tunnelling; Internet; Control Networks

Abbreviations:

IoT: Internet of Things; IIoT: Industrial Internet of Things; ACN:

Architecture for Control Networks; AYIYA: Anything In Anything; CIP:

Common Industrial Protocol; ODVA: Open Device Net Vendors Association;

DNP3: Distributed Network Protocol Version 3

Opinion

During last 5-7 years in industry, at the different

kinds of transport, in energetic field, etc. are very actively

implementing data exchange technologies between separate devices, device

groups and networks. These technologies based on Industry 4.0 (4th

industrial revolution), IoT (Internet of Things), IIoT (Industrial

Internet of Things) concepts. In accordance with these concepts a lot of

different devices became smart, possessing of own CPUs, memory and

different wired and wireless interfaces for external data exchange. Some

of them (like complex PLCs) allow to unite different industrial network

segments, having sufficient productivity and much lower cost compared

to computers [1].

From the beginning of 90th years of 20th

century in industry are very popular some protocols and data transfer

technologies, most known are ASi, ProfiBus, Field Bus, HART, Mod Bus,

CAN, BAC and so on. But in connection with Internet development and

forth coming of absolutely new challenges were created some protocols,

based on TCP/IP. These protocols allow to perform remote control of

complex technical systems for enhancement of control quality, decreasing

response time for force majeure situations and cost for control and

exploitation of such systems. Protocols ProfiNet, Mod Bus/TCP,

Ethernet/IP, Ether CAT became well known; they are compatible with

previous generations, but allow to solve fundamentally new tasks. But in

some situations by cost/productivity ratio win protocols and

technologies, which don't have wide spread, but firmly hold theirs

niche. Some of them are described below.

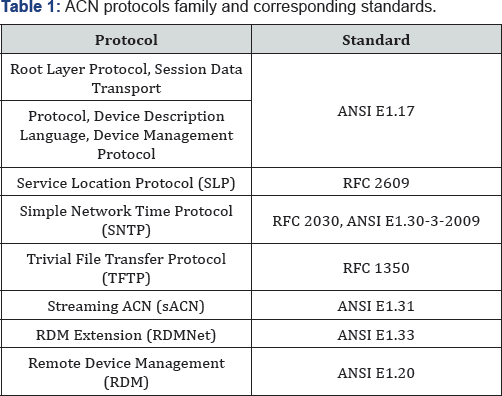

ACN (Architecture for Control Networks) is network control protocol, initially destined for entertainment industry [2]. It has open source code and maintains some subordinate protocols (Table 1).

AYIYA (Anything In Anything) is network protocol for tunnelling between IP-networks and controlling there [3].

Very often it's used for IPv6 packets transit through the networks

based on IPv4 protocol. Network security is provided with absence of

addresses and content of tunnelled packets falsification possibility. At

least one of two tunnel endpoints allows mobile devices connecting.

CIP (Common Industrial Protocol) is the set of standards [4],

which are maintained by Open Device Net Vendors Association (ODVA). CIP

extensions are CIP safety, CIP Sync and CIP Motion protocols. CIP

contains full set of requirements and possibilities

for complex automation systems and their subsystems development from

following sides: control, information security, motion organizing,

informing. Some most important protocols and industrial data transfer

technologies are based on CIP as well and briefly described below.

EtherNet/IP is open industry protocol, which uses

standard Ethernet chips and cable systems, based also on IEEE 802.3

standard, and serve for input/output real time data exchange and

information messages in Device Net and Control Net industrial networks.

CIP provides common application level between networks, which doesn't

depend on media (cable system). It allows to perform direct routing CIP

messages in Ether Net/IP, Control Net and Device Net networks.

Depending on application requirements EtherNet/IP

network may be stand alone or combined with Device Net or Control Net

networks for additional flexible information and control services

realization. EtherNet/IP transfers big user, configuration and

input/output data volumes in the same high speed network; tightly

associates technological and corporate operations; facilitates technical

maintenance expenses decreasing thanks to existing network resources

and technical facilities using; allows to commercial and industrial

technological levels to coexist in the same network; works with TCP/IP

and HTTP protocols.

DNP3 (Distributed Network Protocol, version 3) is a set of communication protocols [5],

which are used for data transfer between components in automation

systems. It's developed for communications between different types of

equipment for data acquisition and control and described in IEEE 1815

standard. In SCADA systems DNP3 is used by SCADA master stations

(control centers), Remote Terminal Units (RTU) and different Intelligent

Electronic Device (IED). It uses 3 levels of OSI model (data link,

transport and application) and contains Secure Authentication v5

mechanism, which allows to master or remote DNP3- system uniquely

determine, that connection is established with legitimate user or host,

but not with malicious user.

HART-IP (Highway Addressable Remote Transducer) protocol [6]

based on standard Ethernet IEEE 802.3 hardware and cable systems

(twisted pair and fiber optics) and with Wi-Fi IEEE 802.11 equipment,

that's why it's possible to use it with standard network switches,

routers, access points, cables and connectors. It may be used in

redundant mesh or ring topologies and with PoE (Power over Ethernet)

power supply standard by twisted pair Possible data transfer rates are

10Mbps, 100Mbps and 1Gbps. HART network, including devices working with

Wireless HART protocol, is compatible with office and industrial

LAN-switches, fiber optics media converters, Wi-Fi access points and

equipment. Compatibility with classic HART protocol allows to put

corresponding gateways into action and to work with classic analogue

4-20mA technologies. Using IP as base interaction protocol allows

HART-IP to work in the same network together with multiplicity of

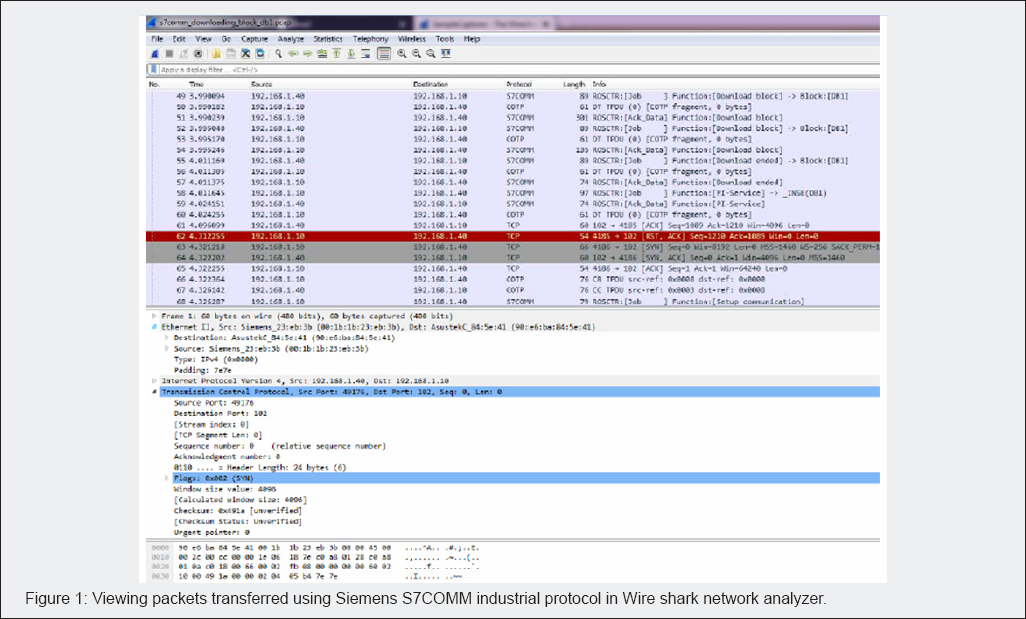

protocols, based on IP and Ethernet (Figure 1).

More than 60 millions devices with HART protocol

supporting are installed in the world. HART over Ethernet or HART-IP

widen HART accessibility in local internal industrial networks with

interconnection with corporate networks and ERP (Enterprise Resource

Planning) software.

Variables and diagnostic data in HART are

encapsulated in HART-IP packets. It allows to realize real time

processes in existing corporate networks and to use corporate VPN

(Virtual Private Networks).

For more articles in Open Access Journal of

Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

To read more...Fulltext please

click on:

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555561.php

Comments

Post a Comment